The MATRIS workpiece handling is designed for a workpiece weight of 44 lbs. and workpiece sizes of up to o 5.9" x 4.7".

The workpiece magazine of the GX 7 is available with 14, 20 or 26 pallet tables. Maximum workpiece weight per pallet is 77 lbs. and a diameter of up to 5.9", depending on the version.

The RPS offers space for up to 21 pallets.

DMG MORI offers flexible workpiece handling and palette automation systems to support its customers on their path towards autonomous manufacturing. Automation solutions are available for all DMG MORI machines from a single source. The range of services extends from standard automation and customized automation solutions to complete turn-key solutions.

Automation solutions from DMG MORI include:

- MATRIS: Modular workpiece handling offering versatility and variety

- GX 7: Space-saving gantry loader

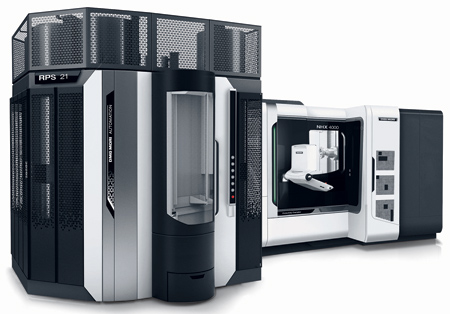

- RPS: High-capacity compact rotary pallet storage system

- Robo2Go 2nd Generation: Flexible automation, simple to program

- PH 150: Pallet handling for 5-axis machining.

Automated machines are crucial components of a digital factory and therefore an integral part of intelligent and networked production. DMG MORI approaches automation solutions for customers as a strategic foundation for competitiveness and future growth. The production plant in Davis assumes an important role in the development and implementation of automation solutions. Additionally, the Automation Systems team provides a full range of services, from technical consultations and budgeting to complete system designs, installation and commissioning. The Automation Systems team work within the Engineering Department along with the applications engineers to provide a seamless process so customers receive a complete automated solution from a single source.

Designing user-specific automation solutions requires a high degree of flexibility and experience. The required flexibility is based on modular building blocks consisting of production cells and systems, which can be configured and adapted individually. DMG MORI also has a holistic approach to the design of automation solutions that considers the entire value creation chain, ensuring the system can be integrated ideally into the process. Automation expertise is fundamental to the efficiencies at the DMG MORI factories, as is also the case at the Davis factory. The California campus consists of both the U.S. factory and DMG MORI's American Research and Development hub, which allows the machine tool manufacturer to be closer to North American customers. Powerful machine tools like the DMC 340 U, three NHX 10000's and two NH 6300 DCGII and the extensive use of automation combined with a highly skilled workforce make Davis a highly advanced factory.

MATRIS: Modular Workpiece Handling

The MATRIS workpiece handling system was recently featured with a CMX 1100 V. Depending on the application, a CMX 1100 V can be equipped with different grippers and can be combined with standardized peripheral modules for washing, measuring or part marking. The structured design of the robot programs and teach functions enable quick changeovers and immediate start-ups in serial production. In addition, the use of MAPPS connected makes maintenance and operation easier. Maximum workpiece weight is 44 lbs. with workpiece sizes up to o 5.9" x 4.7". There is also space available for 14 pallets. MATRIS can even load oversized tools into the tool magazine when combined with the CMX 1100 V. DMG MORI also has the MATRIS mini in its range, offering a very cost-efficient miniaturized form of the MATRIS for an even more compact layout and shorter commissioning times.

GX 7: Space-Saving Gantry Loader

DMG MORI recently demonstrated the benefits of the GX 7 gantry loader on an ALX 2000. This workpiece handling solution is designed to be compact and space saving, as well as easy to set up and operate. Its flexibility is also reflected in the different peripheral equipment that can be configured, such as washing, measuring or part marking. The workpiece magazine of the GX 7 is available with 14, 20 or 26 pallet tables. Maximum workpiece weight per pallet is 77 lbs. and a diameter of up to 5.9", depending on the version. Travel speeds of 180 m/min in the X-axis and 200 m/min in the Z-axis make the GX 7 fast as well as reliable automation solution, since it comes direct from the DMG MORI factory.

RPS: Rotary Pallet Storage

With its rotary pallet storage system DMG MORI offers an automation solution that is equipped with five pallet stations and a set-up station in the standard version. There are also optional configurations for the NHX 4000 with 14 or 21 pallets, which are arranged on two (14 pallets) or three (21 pallets) levels for space-saving purposes. The control of the RPS is managed directly via the machine control with the aid of the integrated Pallet Manager software.

LPP: Linear Pallet Pool

With the DMG MORI LPP, the linear pallet systems can connect up to 10 machine tools and a pallet storage system for up 199 pallets. For loading and unloading, the LPP integrates up to five set-up stations, each of which can be managed and scheduled independently by DMG MORI's exclusive Linear Pallet System cell controller. The maximum workpiece size the LPP can handle is o 133.85", a length of 78.74" and a weight of up to 22,000 lbs.

Robo2Go 2nd Generation

DMG MORI developed the Robo2Go 2nd Generation as a flexible robotic automation solution for the CLX series turning centers as well as the turn and mill complete machining centers of the CTX TC series. Due to its new software, the second generation can be operated intuitively. The processes can be created quickly and simply with the Robo2Go 2nd Generation based on predefined program modules without any knowledge of robot programming.

Teaching the robot during set-up for a new workpiece takes less than five minutes, making the Robo2Go 2nd Generation an ideal and flexible solution for small- and medium-sized batches.

PH 150: Pallet Handling

Another example of available pallet systems from DMG MORI, the DMU 50 3rd Generation was recently demonstrated with a PH 150 pallet handling solution. The 5-axis milling machine is known for its versatility in machining complex parts. Combined with the PH 150, it allows an efficient and autonomous production of workpieces over longer periods. The pallet handling offers space for up to 24 pallets with a maximum pallet size of o 19.68" x 19.68". It is designed for a workpiece weight of 551 lbs.

WH3: Compact Automation

The DMP 70 offers a flexible automation connection from the right, left or front of the machine. DMG MORI recently demonstrated this compact machining center with a WH 3 workpiece handling system. The entire automation solution has a space requirement of just 94.72 sq. ft.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com