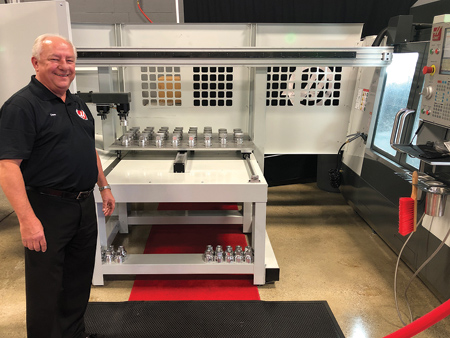

Dave Tucker, President of Haas Factory Outlet-A Division of Midwest Manufacturing Resources, Inc. with the all-new Haas Mill APL loading a Haas VF-2SS.

Students from Cuyahoga Valley Career Center (CVCC) working with HFO/Midwest's Application Engineering Team.

(l-r) Carson Banks; Josh Darty-Berry; Mitch Suder; Trevor Grant, HFO/Midwest; Rich Parrott, Instructor, CVCC; Casey Schultz, HFO/Midwest; Luke Walsh; Jeff Johnson, HFO/Midwest; Matt Yako; and Brett Caulder, HFO/Midwest

All-new Haas Lathe APL loading the redesigned Haas ST-20Y Multitasking CNC Lathe with Y-axis and Live-Tooling at Haas Oktoberfest at HFO/Midwest

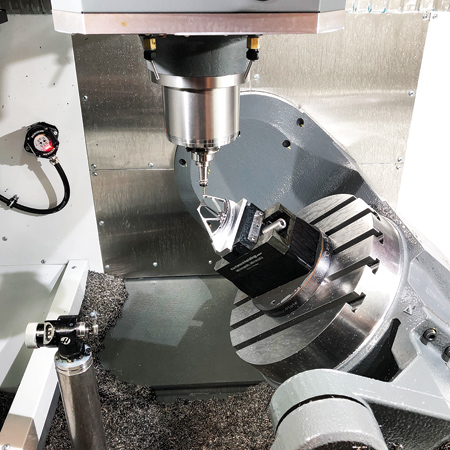

All-new Haas UMC-500 Universal Machining Center performing live cutting demonstrations.

Cuyahoga Valley Career Center student Luke Walsh holding a restrictor plate he machined on a Haas VF-3YT/50 50-taper VMC during Haas Oktoberfest at HFO/Midwest.

Manufacturers and educators from Ohio, Kentucky and West Virginia attended the recent Haas Oktoberfest hosted by Haas Factory Outlet-A Division of Midwest Manufacturing Resources in Twinsburg and Springboro, OH. Several new machine tools and accessories by Haas Automation were demonstrated for the first time outside of factory events.

The main attraction at Haas Oktoberfest was the all-new Haas EC-500 5-axis Universal Machining Center. "Starting at under $120,000, the 5-Axis Universal Machining Center (24 in x 16 in x 16 in) with 400 mm integrated 2-axis trunnion rotary table brings simultaneous 5-axis machining to many shops that until now may have considered the technology too expensive. And with a footprint that is similar to that of a Haas VF-2 vertical machining center (VMC), it does not require an excessive amount of floor space," said a company spokesperson. Also demonstrated was its big brother, the all-new UMC-1000 (40" x 25" x 25"), with a 635 mm integrated 2-axis trunnion rotary equipped with an optional HSK spindle.

New innovations in automation from Haas were also demonstrated at the event. Midwest manufacturers got their first look at an all-new Haas Mill APL (Auto Parts Loader), which offers a simple way to automate part production on small VF series VMCs. It integrates seamlessly with the Haas control, and features a simple set-up interface that will have shops fully automated in minutes, loading and unloading parts for unattended machining. A Haas Lathe APL (released at IMTS 2018) was also demonstrated.

"We are so excited to demonstrate innovative new technologies never before seen, outside of factory events, at this year's Haas Oktoberfest," stated Dave Tucker, President of HFO/Midwest. "We demonstrated two all-new APLs that manufacturers can purchase for about $30,000 as well as a 5-axis Universal Machining Center that starts at under $120,000. I honestly believe the technology and price point of these new products will give American manufacturers the competitive advantage they need to bring more work back to the USA."

As a strong supporter of local educators, HFO/Midwest partnered with Cuyahoga Valley Career Center (CVCC) to allow five of their students the opportunity to operate machines during the event. This gave them a unique opportunity to network with local manufactures while gaining critical hands-on experience operating the latest CNC machine tool technology.

Additional machines performing live cutting demonstrations included:

- VF-3YT/50 50-taper VMC with extended Y-axis

- VF-2SS VMC integrated with a Haas Mill APL

- Newly "refreshed" ST-20Y multitasking CNC lathe being loaded by a Haas Lathe APL

- ST-15Y compact CNC lathes with Y-axis

- ST-10 CNC lathe

- TL-2 CNC toolroom lathe.

Attendees were able to network with a wide variety of leading tooling and accessory suppliers, many of whom had displays set up alongside the machines.

HFO/Midwest-Twinsburg Tech Center

1993 Case Parkway North

Twinsburg, OH 44087

800-833-0246

www.hfomidwest.com

HFO/Midwest-Springboro Tech Center

95 Commercial Way

Springboro, OH 45066