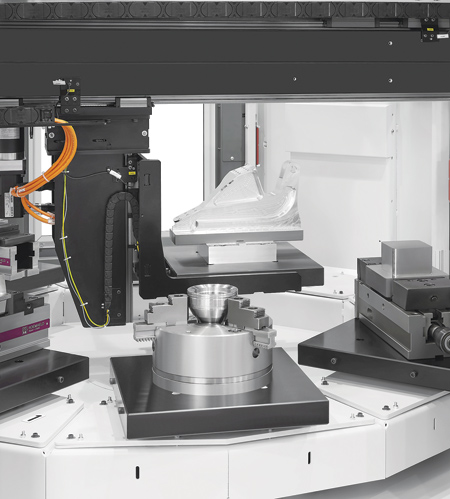

Variocell Pallet interior

Chiron FZ 165-axis VMC with Variocell Pallet

CNC machining centers from CHIRON are designed to combine consistently high production quality, flexibility, low unit costs and short lead times for an optimal process. The addition of the Chiron Variocell Pallet automation cell enables the new high-efficiency FZ/DZ 16 series vertical machining center (VMC) to produce small batches of a variety of workpieces in an even more productive and flexible way.

Variocell Pallet allows different raw parts to be clamped in one of 10 pallets mounted on a rotary table. The handling system guides one raw part after another to the machining center and removes the machined workpieces together with the pallet after the machining process is complete. A palletized part can also be machined while another is loaded into the 5-axis machining centers.

The Variocell Pallet can access the machining center work area with a transfer trolley, which is equipped with driven rollers and can be moved in three directions, avoiding inflexible rail-type systems. With minimal space requirements, the automation solution is always accessible to the operator and can be loaded and unloaded manually.

The FZ/DZ 16 is not only available with Variocell Pallet, but also with the modular Variocell System, a robot-based automation solution adaptable to specific customer applications. With the individually configurable Chiron Variocell, users can increase the efficiency of the Chiron machining centers. The Variocell System offers a variety of space-saving options to meet demanding customer production requirements.

CellLine: Convenient Control for the Entire Manufacturing Cell

The new CellLine from the Chiron SmartLine portfolio is another automation highlight: CellLine allows the entire manufacturing cell, including robots, to be controlled via a single operating panel. CellLine can be equipped with a modern order management function alongside set-up and diagnosis functions for all assemblies. An internet-capable version is also available to enable remote access via the cloud and in several languages.

Variocell Uno Retrofittable to Older Machines

The integrated automation solution Variocell Uno, a compact robot cell, can be used to enhance the productivity of older machining centers. This solution combines a workpiece handling robot and a workpiece storage unit with space for up to 24 pallets within floor space of less than 1 sq. m. The solution can be expanded by a variety of equipment options, such as measuring, light assembly, part marking and more or can be individually adapted to the needs of larger scale production in the Variocell System version.

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info@chironamerica.com

www.chironamerica.us