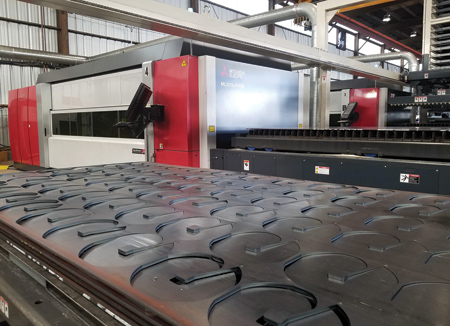

DSW's load/unload system gives them the capacity to provide same-day and next-day services for customers.

MC Machinery's eX FIBER laser with SmartFlex automation system has improved output and efficiency and helped propel DSW to a 45% increase in sales over a two-year span.

DSW also has two Mitsubishi Diamond BB press brakes, which help the company offer a full range of services.

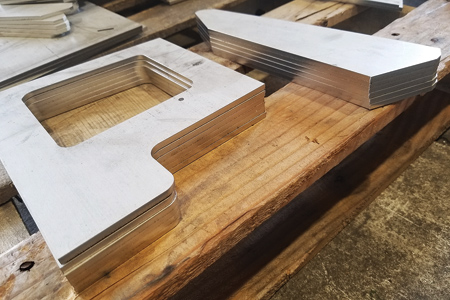

DSW has been able to run aluminum, stainless steel and carbon, among other materials, on its Mitsubishi fiber lasers.

When Dixie Saw Works (DSW) began in 1943, it was a small Birmingham, AL-based converting knife company. Six decades later, DSW has expanded well beyond just providing quality knife parts. Today, the shop provides finished and semi-finished 2D parts to customers across the Southeast.

The journey from that once-small job shop to today's 85,000 sq. ft. facility-which only continues to grow-is in a big part due to DSW's owner, Chris McIlvaine. When he took over in early 2000, he looked to internalize as many processes as possible and sought out opportunities to grow the business.

This growth not only applied to diversifying their customer base, but also adding new advanced machinery and fabricating technology to the factory floor to diversify their services too. McIlvaine knew that if DSW had the infrastructure and capabilities to deliver on customer needs quickly and efficiently, that demand would follow.

"We call it the 'Field of Dreams' business model. We added the equipment-the capabilities-and then went out and marketed to customers," said McIlvaine.

The facility now includes a wide range of fabrication options, from laser to waterjet to plasma cutting. The company also offers additional services, such as bending, welding and painting. But the company continues to grow and evolve as new fabricating technology makes its way to the shop floor.

Making the Switch to Fiber Lasers

In early 2018, DSW installed two Mitsubishi eX-F 6 kW FIBER laser cutting machines from MC Machinery to upgrade their capabilities and replace older CO2 lasers, from MC Machinery as well. Later that year, they installed two additional 8 kW eX FIBER machines and a SmartFlex 16-shelf tower automation system in an effort to further increase throughput.

"While the CO2 lasers were still getting the job done effectively, the addition of the 6 kW and 8 kW fiber lasers offered faster processing speed, ease of operation and the advanced reliability of newer technology," said a DSW spokesperson.

"The CO2 lasers were anywhere from five- to 10-year-old machines. With the technology moving forward so fast, we figured we would go ahead and get these brand-new machines. We also found that we were saving around 50% on electricity costs by switching to the fibers," said Adam Witherspoon, Technical Outside Sales Engineer at DSW.

One of the main application metrics the company looks at when quoting jobs or parts is cycle time. Compared to the older CO2 lasers, the fiber lasers deliver a substantial decrease in cycle time for lighter gauge material. There is also a significant decrease in set-up time, especially when moving from different thickness levels or types of materials. While set-up averaged 15-20 minutes with the CO2 lasers, Witherspoon noted that it is virtually nonexistent with the fiber lasers.

These processing speeds enable DSW to stay competitive, if not ahead of the competition, when it comes to lead times.

"Our customers tell us we are unique in that we are flexible enough to be able to respond to their needs quickly. A lot of our competitors offer three- to four-week lead times on cut parts and you know, if we need you to, we can be reactive same day, next day service, so on," said Witherspoon.

"Even with the improved output and efficiency, the fiber lasers still hold DSW's high-quality parts to the highest standards," said the spokesperson. "Not only has surface finish and edge quality improved, but cuts are consistent across a range of materials with fewer variables to manage. This is because the eX-F comes standard with Mitsubishi's all-in-one Zoom head, which automatically adjusts along a wider focal range than traditional lenses. By ensuring the optimal spot size for every material type and process, the laser delivers on speed, quality and faster feedrates for any thickness level.

"The benefits of upgrading to fiber laser machines have not only increased efficiency and edge quality though," added the spokesperson. "These new machines are unlocking big opportunities to grow the business."

Expanding the Potential for Profits

While DSW sells to fabricators and OEMs of all sizes spanning the automotive, mining, retail display, agricultural equipment and power transmission industries, the eX-F lasers and automation system have opened new doors.

Because the fiber lasers can process such a broad range of materials, DSW has actually been able to move a considerable amount of production over from the waterjet and plasma machines. The SmartFlex automation system has also been instrumental in helping move some of these parts over and processing them in a more cost-effective way.

"The two 6 kW fibers and the addition of the two 8 kW fibers and tower system give us an incredible amount of extra laser processing capacity, allowing us to be competitive in several new markets. The output of these machines has literally created a new department to deal with the number of parts being produced," said McIlvaine.

Since upgrading, DSW has seen a significant lift in sales by about 45% in 2018 alone, and is starting to pursue larger OEM customers by marketing full-production capabilities.

Looking ahead, McIlvaine knows the fiber lasers will only continue to deliver on their promise of helping grow the company's capabilities-and maybe even help DSW reestablish Birmingham as a Steel City once again.

For more information contact:

Dixie Saw Works

816 30th Street North

Birmingham, AL 35203

205-322-2021

www.dswcutting.com

Mitsubishi Laser

c/o MC Machinery Systems, Inc.

85 Northwest Point Blvd.

Elk Grove Village, IL 60007

630-616-5920

mitslaser@mcmachinery.com

www.mitsubishi-world.com