Servo Drives Detect and Correct Following Error Automatically

April 1, 2016

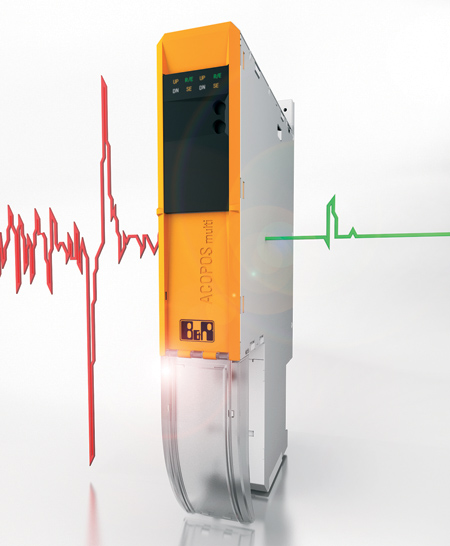

Repetitive control provides following error compensation for ACOPOS servo drives from B&R to improve the accuracy of production processes with stationary disturbances.

B&R has expanded its ACOPOS line of servo drives. Repetitive control, B&R's latest advancement, improves the accuracy of production processes with stationary disturbances by using predictive following error compensation. The performance of the machine or system is increased without a great deal of additional effort. Repetitive control is available for all ACOPOS models by installing a firmware update.

"When using position-controlled drives with constant speed, mechanical conditions can cause stationary disturbing torque fluctuations, which often results in following error localized to a certain area. Optimizing the drive controller configuration can minimize these lag errors but will not be able to completely prevent the disturbance," said the spokesperson.

Embedded in the standard speed control loop for the ACOPOS drive family, repetitive control adjusts the torque setpoint of the drive in a way that reduces the periodic portions in the speed or following error. The algorithm undergoes a constant learning process so that changes to the load profile - caused by wear, for example - have no effect on the drive due to predictive compensation for disturbances.

Available as an add-on to the standard control procedure, active disturbance suppression is designed to be easy and intuitive to configure, not even requiring a mathematical model due to the adaptive nature of the algorithm.

For more information contact:

B&R Industrial Automation Corp.

1250 Northmeadow Parkway, Suite 100

Roswell, GA 30076

770-772-0400

office.us@br-automation.com

www.br-automation.com

< back