Before deciding whether to recondition or repair a defective chuck, companies can initially contact Royal Machine & Tool for suggestions. It may be recommended to have the chuck forwarded to the factory where they will provide a free evaluation and proposal.

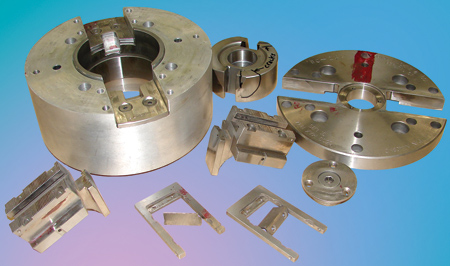

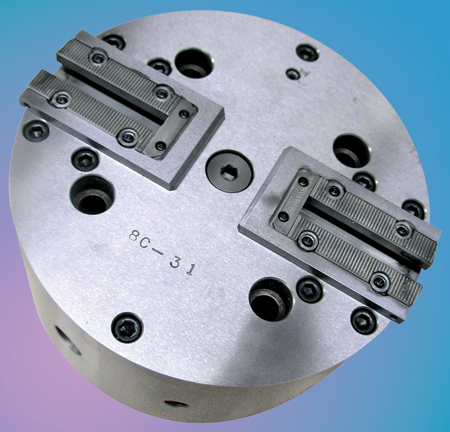

After evaluating the defective original chuck, reconditioning was recommended to provide new chuck standards, one year full warranty (the same as a new chuck) and cost savings over a new chuck.

Royal Machine & Tool Establishes Reconditioning & Repairing Group

"The establishing of our new Reconditioning & Repairing Group provides our customers with a team of engineering, designing and machining specialists experienced in the overall service of repairing and refurbishing of their damaged chucks," said Guy Byrne, Senior Vice President & General Manager.

"In this time of difficult economic decisions, replacing existing worn or damaged chucks with new chucks is not always the best decision. Reconditioning chucks costs less than 50% of buying a new chuck. This allows having two chucks reconditioned like new for the same price as a new replacement chuck and includes a one year full warranty (the same as a new chuck)."

"And this is exactly the reason we have developed our new Reconditioning and Repairing Group, to allow our workholding specialists to concentrate their expertise in rebuilding chucks and assisting our customers in making the right decision when chucks become worn or damaged."

Most brands of chucks including National Acme, Goss & Deleeuw, Kaufman and New Britain can be reconditioned.

Initially, customers contact Royal Machine to discuss their requirements. Then, the chuck will be disassembled, cleaned and evaluated at no charge. Should they not be too badly worn or damaged, Royal Machine will recommend either reconditioning or repairing and then provide a detailed cost estimate. Once the decision is made to proceed, the chuck will be quickly reconditioned and tested, and delivered with like-new tolerances.

"In addition to cost savings, there are four specific reasons for customers to consider reconditioning or repairing a chuck," said Bernie McAloon, Sales Manager:

1. Does the chuck visibly appear to be worn?

2. Has an accident broken something in the chuck?

3. Has the chuck begun to lose its gripping?

4. Has the chuck begun to lose its accuracy?

For more information contact:

Bernie McAloon, Sales Manager

Royal Machine & Tool Corp.

P.O. Box Y

4 Willow Brook Drive

Berlin, CT 06037

860-828-6555

royal@royalworkholding.com

www.royalworkholding.com