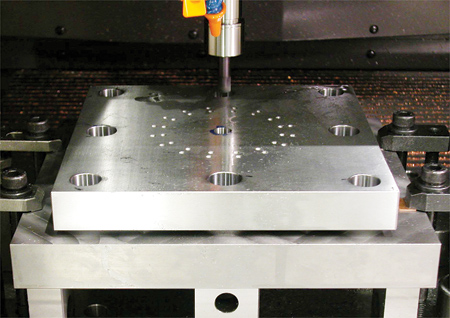

Lamp Mold

Hardened Steel/Cemented Carbide

Methods Machine Tools, Inc. offers the YASDA YMC 430 Version II, a Micro Machining Center that is designed for ultra-precise manufacturing and fine surface finishes required on small, complex features in parts and dies / molds for industries such as medical and semi-conductor. Linear motor-driven axes and a highly rigid machine structure offer users the highest speed, precision and surface quality machining in its class. The YASDA Micro Center YMC 430 Version II has a high-speed 40,000 RPM spindle and is available with 3-Axis or 5-Axis capabilities.

"We are pleased to offer a micro hard milling solution from YASDA for our customers who manufacture molds and components with challenging, micro-sized angles and geometry," said Steve Previti, YASDA Product Manager, Methods Machine Tools, Inc. "A highly rigid, symmetric frame design and unique thermal distortion stabilizing system provides consistency and repeatability." The YASDA YMC 430 has a linear positioning and circularity accuracy of less than one micron (according to ISO 230-2 1997).

The HSK-E32 spindle on the YMC 430 is designed and manufactured by YASDA to minimize vibration for micro milling applications, including roughing to finishing on hardened steel and other exceptionally hard materials. A symmetrical H-shaped column and a low center of gravity provide high rigidity to the YMC 430 machine structure.

The YMC 430 X-Y table has linear guideways and a linear motor drive, enabling highly precise machining and excellent vibration dampening. The linear motor drive includes optical scales that support and sustain submicron milling performance.

In the optional 5-axis micro milling capability, the YMC 430 is equipped with a direct drive motor-driven, high-precision tilting rotary table. This combination provides multi-face indexing and machining, as well as simultaneous 5-axis machining without re-chucking. Applying the direct drive motor to a tilted rotary axis creates backlash-free, high-speed, high-precision positioning.

The YASDA Micro Center YMC 430 Version II has X,Y,Z travels of 16.5" x 11.8" x 9.8" (420 mm x 300 mm x 250 mm). The table work surface measures 23.6" x 13.8" (600 mm x 350 mm). An automatic tool changer holds 32 tools and is available in a 90-tool, large-capacity configuration. The powerful, user-friendly FANUC 31i-Model B5 control is furnished standard.

YASDA Micro Milling Center YMC 430 Version II application examples:

LED molds - "LED molds for IT industries are one of the most demanding micro milling applications," said a company spokesperson. "Moldmakers must achieve surface roughness to Ra 20 nm. In one example, each die block is made of more than 300 cavities and machining time can take over 100 hours. This is incredibly demanding on long-term machine accuracy. The YMC 430 easily sustains this long cycle time to produce high quality surface finishes on LED molds."

Lamp mold - This mold for a plastic lens requires an approximate Ra of 50 nm on 420 STAVAX equivalent steel. Its form is larger than the LED mold and also requires rough milling capability in hardened steel. The automatically adjusting bearing spindle preload system on the YMC 430 are designed to provide optimal removal rates and tool life.

In a lens mold, or plastic injection molding for medical applications, mold base accuracies are extremely tight. In one example, a pitch accuracy with a ±1 µm is required in the holes. Depending on the depth of the holes on the base plate where square end mills are required, the YMC 430 achieves a dimensional accuracy within ±1 µm, which is equivalent to a jig grinding and boring process.

Punches: hardened steel / cemented carbide - "The YASDA RT10 tilting rotary table helps finish hardened punch dies in one chucking, with the highest 5-axis milling accuracy available," said the spokesperson. By tilting the workpieces and synchronizing the tilting / rotations with linear motions without any backlash, it is possible to use shorter lengths of cutters to enable cutting rigidity and to help machine tiny corners and complicated forms on the dies. Using diamond cutters, it is possible to mill and finish small cemented carbide dies and molds.

For more information contact:

Steve Previti

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

978-443-5388

877-MMT-4CNC (877-668-4262)

sales@methodsmachine.com

www.methodsmachine.com