With the new pneumatic ROBA-guidestop, mayr power transmission provides an innovative braking concept which fulfils the high safety requirements and achieves high performance density without the use of hydraulics.

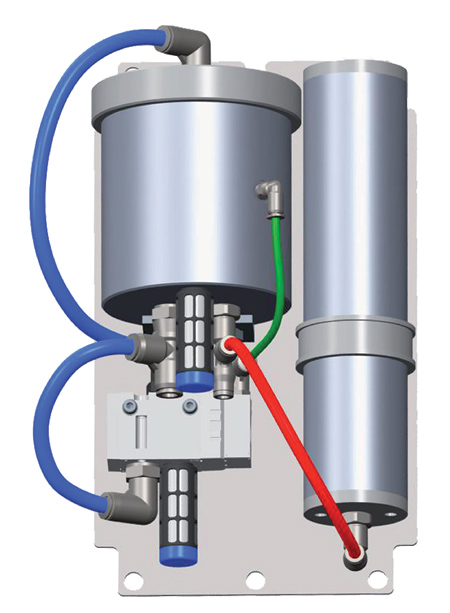

In order to achieve the necessary operating pressure, a compact pressure booster is used in combination with the brake, which increases the pressure existing in the system purely mechanically and without external energy. This innovative concept enables a selective pressure increase directly prior to the individual brake.

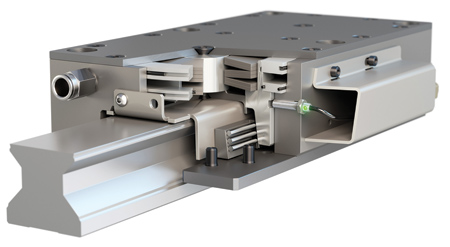

Mayr power transmission is extending the tried-and-tested ROBA-guidestop series with a pneumatically-released version. For machines, in which a hydraulic system is already available, users can still use the hydraulically-released ROBA-guidestop safety brakes. However, in applications where a hydraulics system would have to be installed first in order to operate a brake with high holding forces or in which several brakes would be necessary to achieve the required forces, the pneumatically released ROBA-guidestop safety brake is now used. "It clamps profiled rails equally accurately and backlash-free while achieving the same high holding forces as the hydraulic design of the brake," said a company spokesperson.

Innovative Concept with Pressure Booster

The pneumatic ROBA-guidestop is opened with compressed air at 20 to 30 bar. In order to achieve the necessary operating pressure, a compact pressure booster is used in combination with the brake, which mechanically increases the system pressure from 4 to 6 bar, without the use of external energy. This innovative concept enables a selective pressure increase directly prior to the brake, i.e. directly in the system where the higher pressure is required - as a result, short high-pressure lines suffice. The pneumatic ROBA-guidestop safety brake is available in five construction sizes - each size in both a standard design and in a compact, short design - covering a range of holding forces from 1 to 34 kN. The brake is designed for the different rail construction sizes of conventional linear guidance manufacturers.

The pneumatic ROBA-guidestop safety brake is mounted directly on the masses which should be held. This provides a decisive advantage, especially concerning gravity-loaded axes, where the hazard risk for people should be reduced: Drive elements between the motor and the moving mass, such as spindles, spindle nuts, shaft couplings or gearboxes, therefore have no influence on the safety - as opposed to the concepts using motor brakes, where all drive elements transmit the braking torque to the carriage.

The backlash-free clamping of the ROBA-guidestop directly onto the profile rail provides further advantages: The additional rigidity of the NC axis increases process accuracy, improves machining performance and can provide further technological advantages for heavy machining, for example. The machining produces fewer vibrations. In case of a stationary axis, for example during machining, the brake can absorb the load. As a result it is possible to switch off the drive motor in this phase and remove it from the controls. This eliminates control movements and is therefore gentle on the ball screw spindle. The closed brake absorbs the axial forces. The service life and maintenance intervals of the drive components are extended.

For more information contact:

Mayr Corporation

4 North Street

Waldwick, NJ 07463

201-445-7210

info@mayrcorp.com

www.mayrcorp.com