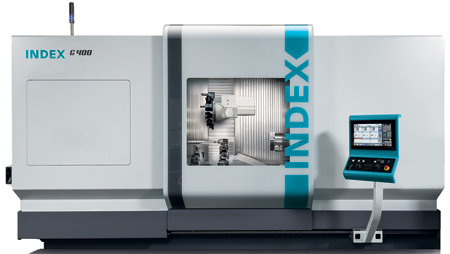

INDEX G400 turn-mill center for high-performance machining of large workpieces.

VDI-40 turret with 12 stations.

In the fall of 2019, INDEX showcased the G420, a new design of a special class of large turn-mill center. The company has now launched the INDEX G400. The main difference from INDEX G420 is that the G400 has a built-in VDI-40 turret with 12 stations in place of the motorized milling spindle.

"The new INDEX G400 turn-mill center is ideal for anyone who wants to carry out complete machining of parts up to 2,300 mm long, where a large portion of the machining consists of turning, and where live tools are sufficient for drilling and milling," said a company spokesperson. "In contrast to its counterpart, the INDEX G420, which is equipped with a motorized milling spindle with a large tool magazine on the upper tool carrier, the INDEX G400 features a VDI-40 turret with 12 stations. The live tools used here also deliver impressive drilling and milling results due to a 7.5 kW motor with 35 Nm torque, and offer fast changeovers via the INDEX W-serration."

A particular feature of this turret is its quill, which enables a large Y stroke of ±100 mm. "Its excellent damping properties and minimal friction are the result of extensive expertise accumulated over many years and a great deal of development work," said the spokesperson. "The quill is based on a polygon contour that can absorb high forces. Further technical highlights include the hardened quill material, which is given a special texture, and the slightly pretensioned sliding guide."

The spokesperson continued, "The mineral cast bed in block design generates high inherent rigidity and, together with the generously dimensioned linear guides in the X- and Z-axes, ensures the excellent stability and damping properties. In addition, the ratio of stationary to moving masses with a factor of significantly more than five not only promises excellent rigidity, but also delivers outstanding dynamic properties with a low level of vibration."

In the standard version of the INDEX G400, the two lower VDI-40 tool turrets can be moved ±70 mm, both in the X and Z directions, and also by means of a linear Y-axis. They each provide 12 stations, all of which can be equipped with live tools. "This means that there are enough tools available to cover even the most demanding tasks without any additional set-up, and makes the large turn-mill center the right choice for small batch sizes too," said the spokesperson. If even more tools are required, the two lower turrets can be equipped with 18 stations each, but without the Y-axis.

Due to the spacious working area and the large distance between the main and counter spindles, simultaneous use of all three tool turrets is possible at the main and counter spindles with no risk of collision. The turning length of up to 2,300 mm allows a wide range of parts to be machined economically. An optional turret steady rest can also be mounted on the turrets. Both working spindles are fluid-cooled.

In the A8 version, there is bar clearance of 102 mm or the possibility of using size 315 mm clamping devices (340 mm diameter in rotation). The A11 version is designed with a bar clearance of up to 120 mm, with a maximum chuck size of 400 mm. With their high dynamics, power, and torque (A8: 41 kW, 920 Nm/A11: 43 kW, 1,000 Nm), the motorized spindles are suitable for productive turning operations.

To enable automated operation of the G400, INDEX offers two different integrated handling units for loading, unloading and removal of remnants for small- to medium-sized parts weighing up to 20 kg. Since the parts are discharged in the area above the spindle, the maximum diameter of the 2-axis version is 160 mm. The 3-axis tool handling system features an additional swivel axis, allowing parts up to 250 mm in diameter to be moved.

INDEX is a supplier for high-end automation solutions with robot support. For the solution implemented on the INDEX G400, the development team chose a modular design that allows different units for operations such as loading, measuring and cleaning to be docked to the largely autonomous standard robot cell from two sides. Loading and unloading takes place via the machine door.

The INDEX G400 is controlled by a Siemens Sinumerik 840D SL. It features an 18.5" touch terminal and the INDEX iXpanel cockpit system, which makes it easy for users to integrate their machines in network structures and use INDEX's own IoT platform iX4.0.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

us.index-traub.com

SOUTHWEST

TX

Prosper Machine Tools, LLC

7415 Whitehall Street, Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

NM

AME, Inc. (Adv. Mfg. Eng., Inc.)

5770 Clarkson, Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AR, LA

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

SOUTHEAST

TN, AL, MS, FL (Panhandle)

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

NORTHEAST

N. NY

Britton Machinery Sales

330 Castlebar Road

Rochester, NY 14610

585-721-4160

MA, CT, RI, ME, NH, VT, W. PA

INIRAM Precision Machine Tool Inc

333 North Main Street

Middleton, MA 01949

978-854-3037

www.iniram.com

MD, E. PA, NJ, S. NY, DE

Single Source Technologies, Inc.

2192 Winterberry Ct.

Warrington, PA 18976

610-430-3670

www.singlesourcetech.com

MIDWEST

KS, MO, S. IL

Dynamic Machine Tool, Ltd.

84 Hubble Dr., Ste. 200

St. Charles, MO 63304

636-447-2900

www.dynamicmachinetool.com

N. IL

Integrated Machinery Systems

101 N. Prospect Ave.

Itasca, IL 60143

630-250-8305

www.imscnc.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

www.methods-equipment.com

MN, IA, ND, SD, E. NE, W. WI

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

www.halesmachinetool.com

OH, KY, IN

Technical Equipment

10165 International Blvd.

Cincinnati, OH 45246

800-852-0582

www.techequip.com

MI (Upper Peninsula), E. WI

Premier Machine Tool Midwest

P.O. Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com

WEST

AZ

CNC PROS

1502 N 17th Ave.

Phoenix, AZ 85007

602-332-5815

www.cnc-pros.com

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

www.ellismachinery.com

CO, WY

AME, Inc. (Adv. Mfg. Eng., Inc.)

5770 Clarkson, Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

N. CA, NV (Reno and Carson City)

CNC Solutions

1011 Pecten Court, Ste. A

Milpitas, CA 95035

408-586-8236

www.cncsolutions.biz

S. CA, NV (Clark County)

Protek CNC

25 W. Easy Street, Ste. 306

Simi Valley, CA 93065

805-579-9995

www.protekcnc.com