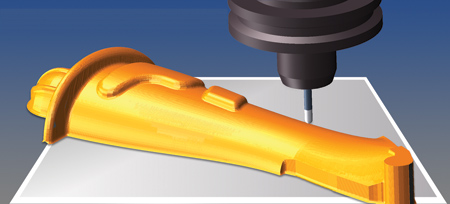

Autodesk Inventor 2017 Certified App: GibbsCAM 2016 seamlessly reads Autodesk Inventor 2017 IPT and IAM files, preserving assigned CAD and hole features, so the GibbsCAM user can use the data for CNC programming and machining parts on all types of turning, milling and multitasking machines.

3D Systems has announced that its suite of GibbsCAM 2016 software for programming CNC machine tools has been certified by Autodesk for Autodesk Inventor 2017 mechanical CAD software. Among other benefits, this certification is designed to assure that engineers and CNC programmers can use GibbsCAM 2016 to program complex and simple parts for machining on all kinds of CNC lathes, mills, turning centers, machining centers and multitasking machines, directly from Inventor and Inventor CAD models.

GibbsCAM 2016 is certified for Inventor 3D mechanical design software under the Autodesk Certified Apps Program, marking the 16th consecutive year that GibbsCAM has been certified under the program. Certification demonstrates that GibbsCAM 2016 is of high quality and provides interoperability with Autodesk's latest release, Inventor 2017, R3.

"Meeting the requirements of the Autodesk Certified Apps Program demonstrates a commitment to shared Inventor-GibbsCAM customers, and ensures that these customers can achieve the highest productivity from Inventor resources with the latest features of GibbsCAM 2016. Integration with Inventor, combined with GibbsCAM's automation features, makes preparation for machining much simpler and faster, providing timesavings for Inventor users. GibbsCAM's short learning curve and unique, shop-friendly user interface provide additional productivity from ease of use, reliability and speed of programming," said a company spokesperson.

Interoperability with Autodesk Inventor

GibbsCAM seamlessly reads Inventor Part Model (IPT) and Inventor Assembly (IAM) files, preserving all CAD, color information and hole features and attributes assigned within Inventor, to provide continuity in recognizing and communicating part and feature attributes. Alternatively, with the GibbsCAM Autodesk Inventor Add-in, Inventor users can transfer files directly into GibbsCAM on the same workstation with the "Transfer to GibbsCAM" menu option. Once machining processes are defined in GibbsCAM, they are automatically updated when the Inventor model is revised. Users can additionally employ the GibbsCAM Plug-in for Autodesk Vault software to allow interaction between GibbsCAM and the Autodesk data management software. The combination of GibbsCAM 2016 and Inventor cover the range of design, manufacturing and product data management across multiple industries. Whether parts have simple geometry requiring general machining, or complex geometry requiring multi-axis milling, multi-task machining or Swiss-style turning, GibbsCAM 2016 easily accommodates the Inventor production environment.

For more information contact:

3D Systems Corporation

333 Three D Systems Circle

Rock Hill, SC 29730

803-326-3900

moreinfo@3dsystems.com

www.3dsystems.com

GibbsCAM

www.gibbscam.com