NUM's new Tool Management Software simplifies control of multi CNC machine tool environments.

NUM has released a new software facility for its latest-generation Flexium+ CNC platform that places an advanced tool management system at the disposal of manufacturers operating multiple CNC machine tools. It is especially suitable for complex high-end milling applications, as well as HSM applications in the mold and die market.

Forming part of the latest version of NUM's Flexium+ software (V4.1.00.00), the new tool management facility provides a comprehensive and accessible database that can either be installed on a server platform for use with multiple CNC machine tools in a large production plant, or can be used standalone on a single CNC machine tool.

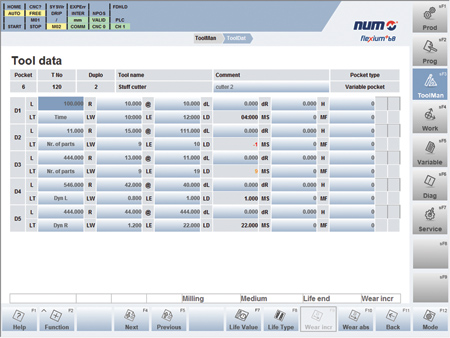

The tool management software includes PLC libraries, as well as dedicated CNC functions and HMI pages. It is designed to handle a large number of tools of different types - including turning, milling and boring - and standard, medium or large sizes. Duplo tools with identical cutting characteristics are also supported, as are different types of tool magazines such as disk, chain or rack. New tool characteristics are managed at maximum speed and maximum feedrate, and the tool life can be monitored over time, by wear amount or by the number of operations. Pre-emptive warning messages are generated automatically whenever specified limits are approached.

The software provides an especially comprehensive set of extensions for tool characteristics. In addition to standard items such as the name, type and number of cuts - as many as 18 of which can be specified - extensions are also provided to handle numerous other factors, including magazine size, life management, technological characteristics such as maximum speed and speed rate, and status/warning indicators.

Developed primarily as a high-end system for complex tasks in milling applications, the software offers NCK features such as a large block look-ahead capability in excess of 1,000, together with very short NCK cycle times. These features also make the system ideal for HSM applications in the mold and die market.

"NUM's new tool management system is easy to use and requires no special software tools," said a company spokesperson. Users simply employ NUM's Flexium Tools software to extend the scope of their project to the database server. A full set of API functions is included to implement all necessary tool operations, together with a number of dedicated functions in NCK firmware. The system also includes different logical HMI list pages for spindle and magazine view, tool view and tool data table, enabling users to visualize the complete content of tool information and current status.

Werner Heimpel, NUM's Product Manager for HMI and Software Tools said, "Manufacturers operating multiple CNC machine tools are often forced to devote significant resources to tool management. NUM's new system can help them to save considerable engineering costs in the long term."

For more information contact:

Steve Schilling

NUM Corporation

603 East Diehl Rd., Ste 115

Naperville, IL 60563

630-505-7722

sales.us@num.com

www.num.com