Long-Baseline Neutrino Facility (LBNF-DUNE)

Main injector tunnel

Scientists at the Fermi National Accelerator Laboratory (Fermilab) are working on research projects that aim to answer fundamental physics questions. How did the universe begin? What are dark matter and dark energy? What is the mass hierarchy of neutrinos? Are there other undiscovered particles beyond the currently known Standard Model of Particle Physics?

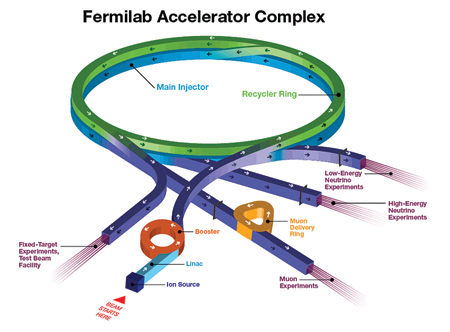

"To address these questions, Fermilab - the premier high-energy particle physics laboratory in the United States - operates some of the world's most advanced particle accelerators," said a Fermilab spokesperson. Fermilab's 6,800-acre facility is located in Batavia, IL, and its particle accelerator chain - with a total length of more than 10 miles - resides in tunnels 25' or more below ground.

Fermilab recently left its history as a collider physics laboratory behind and transitioned into a high intensity neutrino facility in support of international research into particles called neutrinos. In order to create the lab's particle beam, a large number of protons must be accelerated to very high energies. The charged protons are guided by powerful magnets on a circular path before striking a graphite target, which generates secondary particles. These particles decay into neutrinos and other short-lived by-products.

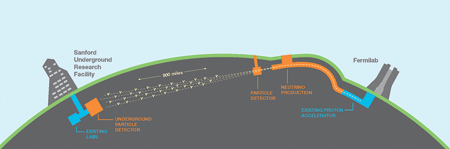

When upgraded for the Deep Underground Neutrino Experiment (DUNE), Fermilab's accelerator complex will deliver 1.2 MW of proton beam power to a graphite target at an energy of 120 GeV, creating the world's highest-intensity neutrino beam. That beam will travel 800 miles through the earth to a detector filled with liquid argon, located at the Sanford Underground Research Facility in South Dakota.

Magnet Alignment

The alignment of the magnets is critical for the optimal operation of the facility. Fermilab uses API Radian Laser Trackers during the installation and routine maintenance to position and inspect the dimensional integrity of the magnets in the tunnel. A maintenance period can last up to three months and requires using laser trackers to facilitate a speedy alignment process. Fermilab requires the laser interferometer technology, as integrated into the laser tracker for precision distance measurements, to comply with the National Institutes of Technology Standard (NIST).

The API Radian trackers are also used to lay the foundation for the alignment of the magnets in the form of a large-scale control network throughout the accelerator tunnel infrastructure. These reference points allow the end user to relocate the tracker anywhere within the tight tunnel enclosure while maintaining a connection to the global control network. The API Radian produces the best results in the range of 0 to 30 m, corresponding to the visible line of sight in many of the accelerator enclosures.

"The API Radian is one of the most compact and least heavy instruments available," said an API spokesperson. "In many cases tunnel enclosures are only accessible through long and steep stairwells, so the equipment has to be hand-carried safely to the work site. Laser trackers are now commonly used at accelerator facilities around the world."

Locating Radiation Hot Spots in the Vacuum Tube

"Fermilab already generates the most intense beam of neutrinos in the world, but the upcoming DUNE experiment will require a greater increase in beam power," said the Fermilab spokesperson. This necessitates the upgrade of specific sections of the accelerator's vacuum system. The existing vacuum infrastructure is not able to accommodate the increased beam size, and limits the machine operation. This puts a much higher demand on alignment requirements for the vacuum pipes, which do not have reference markers and can only be determined by feature measurements.

Fermilab recently purchased an API wireless I-Probe and I-Scan II to support the feature measurement process of beam pipes. The I-Probe/I-Scan II combo allows the teams to measure hidden points on the pipe and acquire a pipe cross-section with many data points in a very short time. This reduces the amount of time that alignment crews may be exposed to higher radiation levels in these areas. These accessories allow the users to navigate in tight spaces within the tunnel that they could not access with just the API Radian and an SMR.

API offers a variety of 3-D metrology technologies as well as customized measurement solutions. Dimensional inspection and metrology services include consulting, calibration, machine tool error mapping, contract measurement, 3-D CAD modeling and reverse engineering.

For more information contact:

Automated Precision Inc.

15000 Johns Hopkins Dr.

Rockville, MD 20850

800-537-2720

info@apisensor.com

www.apisensor.com

Fermilab

Kirk Road and Pine Street

Batavia, IL 60510-5011

630-840-3000

www.fnal.gov