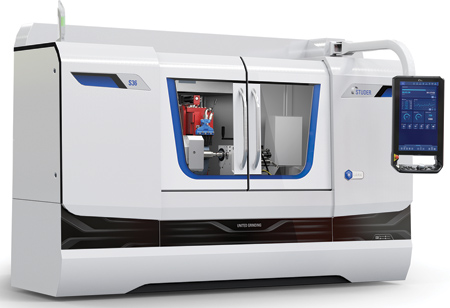

STUDER S36 production cylindrical grinding machine

Grinding head of the new STUDER S36 production cylindrical grinding machine

"Due to the rapid development of eMobility and other alternative drive types, among other things, the demand for suitable grinding machines for a new variety of components in vehicle manufacture is also increasing. That is why STUDER has developed the new S36," said a UNITED GRINDING spokesperson. It will be positioned between the compact S11 for small workpieces and the S22 for medium-sized workpieces.

"Many features of the new S36 are similar to its very successful predecessor, which sold over a thousand units. New functionalities for changing requirements supplement proven concepts. The demand for cost-effective grinding solutions for medium to large series also remains consistently high in eMobility applications," said Project Manager Martin Habegger. "In addition to vehicle manufacturing, the new machine will also be used in the hydraulic, pump and toolmaking sectors."

The S36 has a fixed grinding head, with grinding wheel angles of 0°, 15° or 30° available. The distance between centers is 650 mm and the maximum workpiece weight is 150 kg. Components used in the machine include a Granitan machine bed and a workhead with high-precision roller bearings.

The machine concept is designed for productive external grinding of chuck and shaft components. STUDER serves many different industries with the S36. Its field of application extends from die and mold through the aerospace industry to the production of parts for the hydraulic and automotive industry.

A main feature of the new machine is its large grinding wheel, which has a diameter of 610 mm and initially a maximum width of 125 mm. "This makes the S36 above standard in its category," said the spokesperson. "In addition, the machine comes with C.O.R.E. OS, UNITED GRINDING Group's smart, cross-brand operating system-including touch panel and intuitive operation. Due to the uniform C.O.R.E. software architecture, data exchange between the machines is possible. This is also possible with third-party systems via the integrated umati interface. This interface also provides access to the UNITED GRINDING Digital Solutions products directly at the machine and without the installation of additional hardware. C.O.R.E. creates the technical foundation not just for these and other IoT and data applications, but also for a revolutionary, standard and simple mode of operation."

The newly developed SmartJet nozzles for efficient and automatic coolant supply are fitted as standard, so cooling is now managed by the machine control. A frequency-controlled pump and a dynamic pressure measuring unit are used as central components. These make it possible to precisely adjust the volume flow to suit the process-for rough grinding, fine grinding or finishing. The cooling medium is fed to the grinding wheel via a manifold and flow-optimized, adjustable nozzles. "This concept guarantees precise, efficient and reproducible cooling," said Habegger. "We offer customers the S36 with all of this modern grinding technology at an excellent price/performance ratio."

For more information contact:

UNITED GRINDING North America Inc.

2100 UNITED GRINDING Blvd.

Miamisburg, OH 45342

937-859-1975

info@grinding.com

www.grinding.com