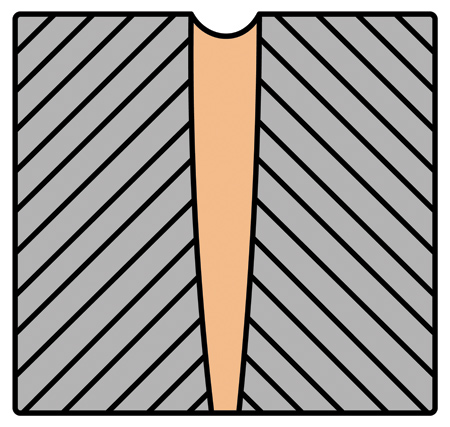

"In contrast to existing thick joint welding methods-which require the costly and time-consuming forming of bevel grooves, chamfers and subsequent filling with extra material-laser welding saves time by conducting deep-penetration welding in a single pass, eliminating the need for multiple runs, layering, filler material and extra steps such as beveling, all the while minimizing the heat affected zone (HAZ) to improve joint strength," said a spokesperson.

AMET, which has experience in the welding market and expertise in designing and manufacturing high precision welding systems and controls, partnered with Civan to build a DBL-based system that offers a turn-key welding solution for thick metal sections.

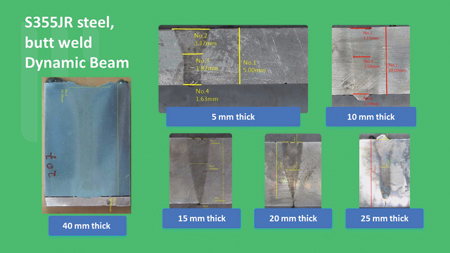

This cross section of a 25 mm weld performed by Civan's DBL on S355JR steel illustrates how reduced HAZ can improve joint integrity in very deep welds.

Civan Lasers' novel dynamic beam laser (DBL) technology is designed to enable single-pass laser welding of 25 mm to 50 mm thick metals. The DBL's megahertz-level frequencies, which expose a broader set of parameters for enhanced control of laser welding processes by using unlimited beam shaping and up to 20 mm of focus position, influence how much control laser welders have over keyhole and melt-pool dynamics.

"These capabilities enable new applications for lasers," said Dr. Eyal Shekel, CEO of Civan. "DBLs are similar to electron-beam technology in its ability to wobble the beam in megahertz regimes. However, DBLs can do so without requiring a vacuum environment."

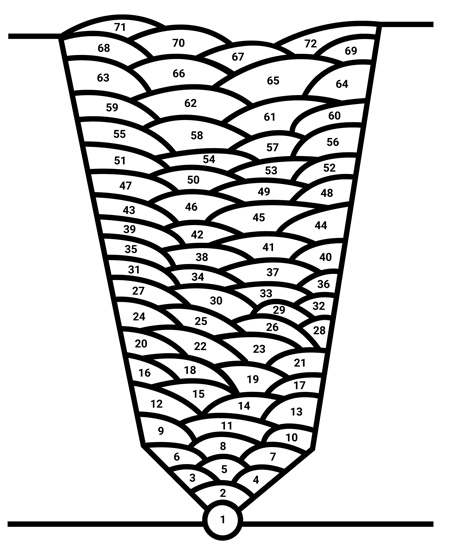

A common process for welding thick sections is submerged arc welding (SAW). Typically, SAW and other processes require beveling the workpiece to allow the torch access to the joint root. The multipass process requires high heat input to the weldment and can generate a large heat affected zone (HAZ) along with distortion.

"Laser welding can focus a large amount of energy to a small spot," said a spokesperson. "However, existing lasers are limited in welding thick sections and therefore are not commonly used. The unique capabilities of the DBL enable thick-metal laser welding for the first time, bringing all the advantages of laser to metals in the thickness of 15 mm to 50 mm. These advantages include eliminating the need for beveling and reducing HAZ and distortion along with vastly higher welding speeds."

To offer a turn-key solution, Civan Lasers and AMET collaborated to develop a laser welding system aimed at thick metals. The companies have partnered to develop the most advanced laser welding system for welding 15 mm to 50 mm metals. The project has won a prestigious grant from the Israel-U.S. Binational Industrial Research and Development Foundation (BIRD Foundation), which aims to support collaboration between Israeli and U.S. companies.

For more information contact:

Civan Lasers

info@civanlasers.com

www.civanlasers.com

AMET

355 Dividend Dr.

Rexburg, ID 83440

208-356-7274

www.ametinc.com