Jergens Custom Quick-Change workholding solutions are designed to maximize productivity and minimize cycle times for customers in numerous industries.

Jergens will feature its product and process expertise at this year's PMTS, April 18-20 at the Huntington Convention Center of Cleveland. To address the rising demand for custom solutions, Jergens' dedicated group helps customers address unique part holding challenges to gain productivity and minimize cycle times on a wide range of CNC machines, including multispindle and multiaxis.

"That can be accomplished in several ways," said Jack Rushlander, Jergens Technical Sales Manager. "We have so many combinations to bring to the table where we start by building the solution around the needs of the part, then plot out fixturing for best machining and optimum number of parts. With small part, high volume manufacturing needs, the Custom Design and Build team looks for opportunities to create high density fixtures to get as many parts as possible in the machining envelope."

Jergens has a history of offering customized solutions, and as such has developed a streamlined process for faster turnaround, which can otherwise be a deterrent to a custom solution. That process has specific milestones that begin with identifying the need and proceed through concept, approval, manufacturing and ultimately delivery. "In the end, a custom solution can be created and delivered in a matter of weeks, and with that, customers are achieving the highest machining access, maximum number of fixtured parts, shortest part changeover and fastest cycle times," said Rushlander. "Updated fixturing combined with the implementation of quick-change represents significant savings, with ROI in as little as a few weeks."

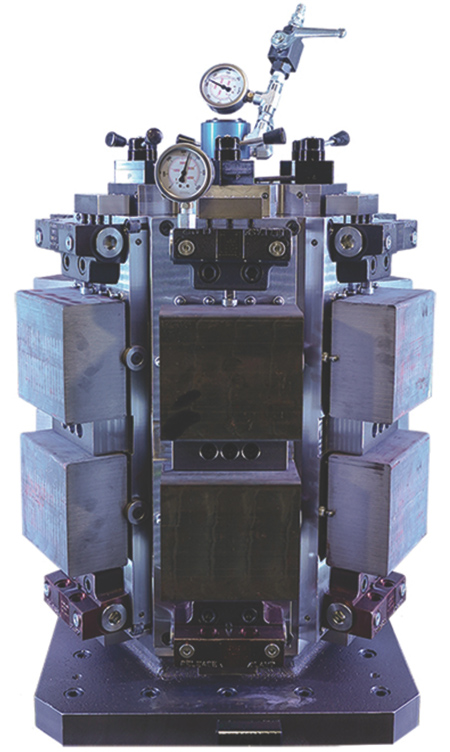

In addition to presenting Custom Design and Build capabilities, Jergens will show and demonstrate modular workholding innovations. Included will be the 5CV self-centering vise; Quick-Loc pallets, receivers and risers; Ball Lock mounting system; ZPS clamping; OK-Vise clamps; cast iron tooling columns; and the in-line machine washdown tool.

For more information contact:

Jergens, Inc.

15700 S Waterloo Road

Cleveland, OH 44110

877-486-1454 / 216-486-5540

info@jergensinc.com

www.jergensinc.com

PMTS Booth 10073