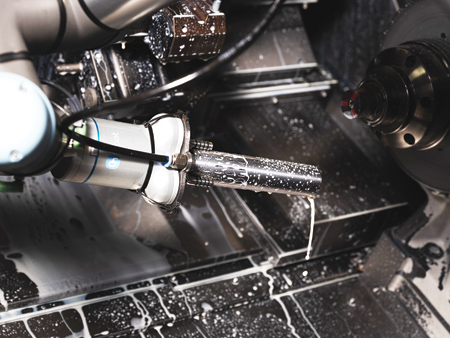

Robotic unload from mandrel in process.

Tyler Burningham inspecting the set-up on the Nakamura-Tome SC-100 lathe.

Tube on mandrel for precision turning process.

The popular SilencerCo Hybrid 46 machined using the HAINBUCH Mando mandrel.

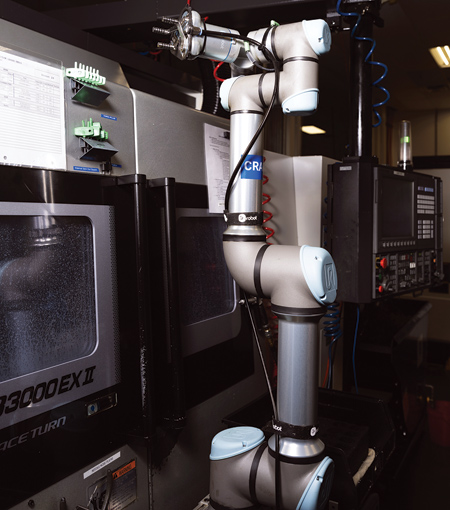

Okuma LB3000 equipped with HAINBUCH Mando mandrel.

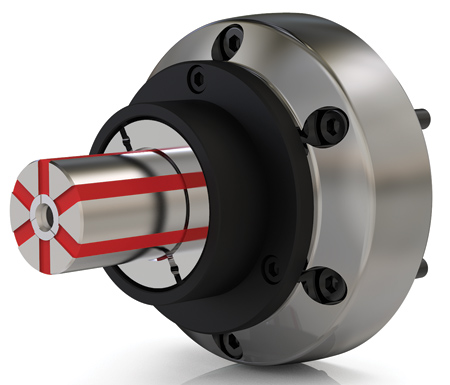

HAINBUCH T812 Mando mandrel with expanding bushing.

Among hunters, competition shooters and firearms aficionados, the popularity of noise suppression devices, commonly known as silencers, is rapidly increasing. This is due to a number of factors, such as the hearing protection they offer, their availability for a wider range of firearms, including shotguns, and the increasing awareness of the fact that they are legal in all but eight states (California, Delaware, Hawaii, Illinois, Massachusetts, New York, New Jersey and Rhode Island).

Despite some misleading portrayals in the media, which depict them as virtually eliminating any noise, the supersonic nature of gunfire results in a distinctive "sonic boom." Even with "subsonic" ammunition, some sound is present, but the use of a silencer can reduce decibel levels substantially. This can be especially helpful, not only in target range situations where multiple shooters can impact even the best hearing protection, but also for hunters who find it inconvenient or, for safety reasons, undesirable to wear protective devices in the field.

SilencerCo of West Valley City, UT, was founded in 2008 for the specific purpose of "creating better products for a larger audience." Since that time, the company has expanded to a 72,000 sq. ft. facility with 194 employees, producing more than 15 commercial silencer models, as well as custom military models and caliber variants.

According to Tyler Burningham, CNC Programmer at SilencerCo, "When a bullet is fired, it is propelled forward by gas expanding behind it. A silencer uses a series of specially designed chambers that provide a larger surface area that traps the gas, creating a lower intensity and decreasing the noise factor. Further benefits include less recoil, as well as reduction of the flash at the muzzle."

To help ensure high performance as well as long life, SilencerCo uses only high-quality materials, including 17-4 and 316 stainless steel, cobalt, Inconel, titanium and aluminum. Tolerances range from .0003" to .0005". Part runs extend from 100 to an indefinite number, depending on the product and production schedule.

"Most of our conventional products are thread mount and feature eight internal baffles," said Burningham. "The typical silencer contains 11 parts, and sizes range from 22LR to 45 caliber, as well as 338 magnum. Manufacturing processes include machining, turning on both conventional and Swiss-style lathes, EDM and, most recently, 3D printing."

To ensure accuracy in critical machining processes, nine of the more than 40 lathes at SilencerCo are equipped with HAINBUCH SPANNTOP workholding systems in both 65 mm and 52 mm sizes. Three Okuma LB3000s are equipped with HAINBUCH Mando mandrels and robot unloaders. Burningham explained: "One of the most critical processes involves ID machining of .050-in. thick tubes. In the past, we experienced significant breakage problems, but since we have incorporated the HAINBUCH Mando mandrel for clamping on the ID, that has not been a problem. In fact, we have automated the unload function.

"A further advantage with the HAINBUCH products is the quick-change collets. The ability to switch collets in seconds with .0002 in. of runout is huge. It delivers the precision we require, saves on changeover time and eliminates scrap. It literally pays for itself."

In addition to achieving the high precision parts that meet SilencerCo's tolerances, the HAINBUCH workholding systems have resulted in other benefits. "For instance, we are able to use standard, rather than specialty, tooling and can prolong the tool's useful life, generating significant savings," said Burningham. "Further, the flexibility of the system has been helpful in fulfilling our stated mission to offer a wider line of products that can be used with virtually all common firearm configurations. Along with conventional pistol and rifle silencers, we offer legacy models as well as the Salvo 12 for shotguns."

Michael Larson, Marketing Director for HAINBUCH America, noted, "As with SilencerCo, more of our customers are citing the need for flexibility in selecting HAINBUCH products. Manufacturers of medium and short runs of multiple products can achieve significant savings in time and money due to the versatility of the system and our quick-change capability. As the cost of high-quality materials and alloys has increased, the elimination of scrap has assumed greater importance."

Larson continued, "The quick-change feature and ease of set-up is common to our collet chucks and our Mando lines. Besides the fast set-up times, customers appreciate the range of sizes available in our standard collets. Where unique applications demand it, our staff works with purchasers to design and produce specially customized workholding equipment.

"Another point that customers appreciate over the long term is the extended life that our high-precision products deliver for their turning equipment. The installation of HAINBUCH products on older lathes enables them to perform with the precision of new machines. Likewise, by specifying HAINBUCH on new lathes, the customer can be assured that, despite ongoing use and wear, their machine will `stay young' in terms of accuracy and performance."

Burningham commented, "Our improved production capabilities and high-quality standards have been extremely beneficial to our distributor network and our increasing customer base. As more firearms users have become aware that silencers are legal in most states and that they are available in models that can be used with virtually any common caliber, demand has increased across the board. Due to SilencerCo's ability to manufacture a great product in a timely manner, we will be able to meet that demand.

"Historically, the firearms industry has always been in the forefront of precision manufacturing. As performance requirements and designs have advanced, the need for repeatability has only increased. The commitment of SilencerCo to the development of products using the latest materials machined to high tolerances maintains that tradition."

For more information contact:

SilencerCo

5511 South 6055 West

West Valley City, UT 84118

801-417-5384

info@silencerco.com

www.silencerco.com

HAINBUCH America

W129 N10980 Washington Dr.

Germantown, WI 53022

800-281-5734 / 414-358-9550

sales@hainbuchamerica.com

www.hainbuchamerica.com