Clean Tube Technology Option for Lasertubes

April 1, 2023

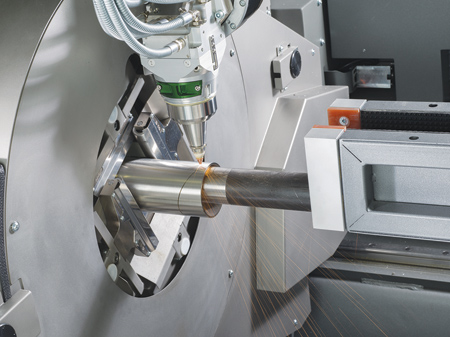

BLM GROUP's Clean Tube Technology probe is inserted into pipes, using suction to capture spatter, gases and vapors produced during the cutting process.

BLM GROUP's Clean Tube Technology, also known as a "spoon," is designed for its lasertube machines to keep the inside of the tubes free of slag, debris and dust. The Clean Tube Technology probe is inserted into pipes during the cutting process and uses suction to capture spatter, gases and vapors produced during the cutting process. This option, which is available for BLM Groups Lasertubes 8" and below, helps produce a clean and dross-free internal finish.

The Clean Tube Technology is especially suited for fabricators cutting stainless tubes for the water treatment, food processing or other clean environment industries, as well as secondary processes that involves tube bending when using a mandrel. The cleaner the inside of the tube, the longer the life of the mandrel. Capturing the debris during the cutting process eliminates the need for a secondary cleaning step after the cutting process, saving time and boosting productivity.

The spoon is matched to each size of lasertube machines, automatically adjusting to the tube diameter. An additional benefit of this technology is that it also helps to stop the laser beam from reaching the opposite side of the tube wall, delivering higher quality processed tubes.

For more information contact:

BLM GROUP USA

46850 Cartier Dr.

Novi, MI 48377-4117

248-560-0080

sales@blmgroupusa.com

www.blmgroup.com

< back