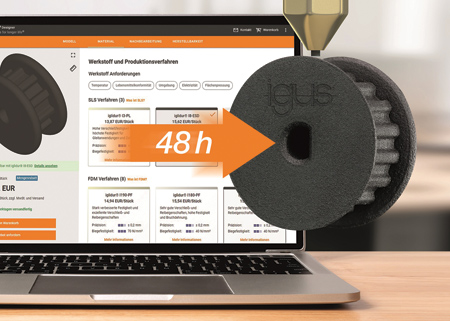

Designers receive their custom high-performance, maintenance-free toothed belt pulleys in just 48 hours via the 3D-printing service.

igus announced it is expanding its 3D-print and online ordering offering to include custom format toothed belt pulleys.

"Toothed belt pulleys are a common component in many machines and are widely used in linear drives of printers, robots and packaging machines. However, if an individual variant is required, developing a custom component can take days or even weeks," said a spokesperson. "To shorten delivery times for special-format belt pulleys, we now offer manufacturing by 3D printing, reducing delivery times from several weeks to just 48 hours."

The spokesperson continued, "In the igus in-house 3,800 sq. m test laboratory, the high-performance polymer iglide i3 competed against an injection-molded and a milled spur gear made of polyoxymethylene (POM) in a pivot test at a speed of 0.1 m/s, a torque of 2.2 Nm and an extreme temperature of 1,440 °C (2,624 °F). All spur gears had a width of 16 mm and 30 teeth. The result: the milled spur gear failed after 12,500 cycles, and the injection-molded variant after 4,000 cycles. The 3D-printed gear made of iglide i3, on the other hand, withstood almost 20,000 cycles."

In addition to iglide i3, we also offer the FDA-compliant version i6 for the food sector and the electrostatically dissipating variant i8 for explosive areas. "All high-performance plastics are robust and wear-resistant enough to be an economical and reliable alternative even to steel and aluminum belt pulleys," said the spokesperson.

"The production of toothed belt pulleys with flanged wheels is particularly complex and is difficult to produce from a single piece of metal using lathes and milling machines," continued the spokesperson. "However, the 3D-print service from igus speeds up manufacturing because the parts are printed in one piece, and the online configurator makes it easy to order."

Customers can upload a CAD model of their part via drag-and-drop on the website to determine a price immediately and place the order. If the customer does not have a digital model, they can configure one within minutes using the belt pulley configurator. Users simply enter specifications such as belt profile and the number of teeth. The configurator then creates a STEP file that users can upload to the website.

For more information contact:

Igus, Inc.

P.O. Box 14349

East Providence, RI 02914

800-521-2747

sales@igus.com

www.igus.com