CADET Level II instructor Jeff Bee shows Jarrod Shumaker how to program the waterjet machine to cut patterns on the bottom and sides of a metal fire pit.

"We can perform CNC programming in four steps because the program is made specific for waterjets," said Jeff Bee.

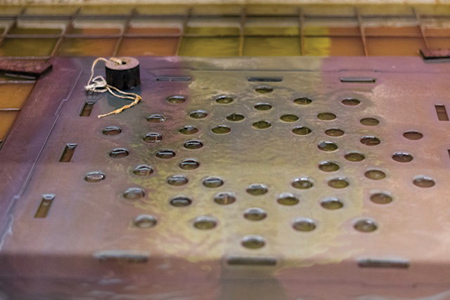

The waterjet machine was assembled by Jeff Bee and Troy Spear at Wardjet. Although commercial-grade, the machine arrived as a kit. Here it cuts the hole pattern for the bottom of the fire pit.

The computer lab portion of the Advanced Manufacturing lab has 20 desktop stations where students learn their programming skills.

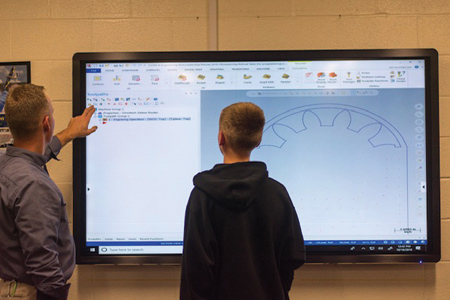

CADET Level I instructor Troy Spear shows RHS Senior Noah Lovas how to program high-speed toolpaths in the Mastercam CAD/CAM software.

"Making the letters is the students' hands-on introduction to CNC. They take a drawing - a DWG file - bring it into Mastercam, scale it, learn to put a tool path to it and nest it," Spear said. "Within an hour, we can have it on the machine, material already mic'd, then nest and make the G-code." Here, Noah Lovas holds a Delta letter made by the students.

Audrey Hepler programs a job into the Haas TL1 lathe, which was purchased with funds earmarked for the Career Tech program. Director of Career Tech Education Brian Bachtel is supportive of his teachers' vision.

CADET Level II Instructor Jeff Bee and Level I Instructor Troy Spear with the new Haas ST-10 Mill-Turn machine.

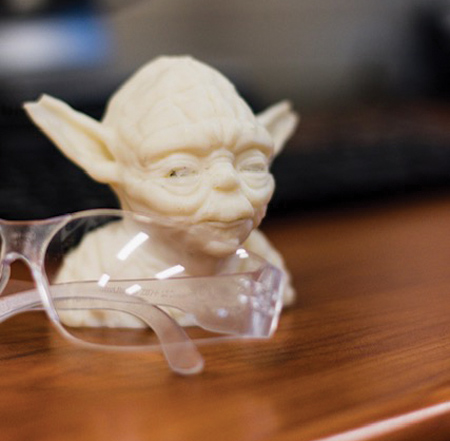

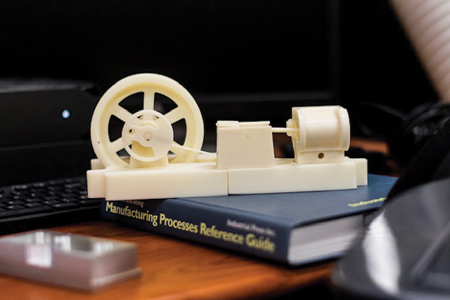

Some prototypes machined by the CADET students.

Wooden Deltas programmed into the software and created on the commercial-grade router.

"If you can dream it, we are going to show you how to draw it, design it, prototype it, machine it, put it together and make it work." That is what students at Kent Theodore Roosevelt High School (Kent, OH) hear from instructor Troy Shear during their first class in the Computer Aided Design and Engineering Technologies (CADET) Program. Later, students visit CADET's Machining Center Lab, which is equipped with routers, lathes, milling machines and even a waterjet machine. They examine models of some of the dreams that students before them have turned into realities.

CADET is one of 26 College Tech Prep Initiatives that students can select under Ohio's Six District Educational Compact. The Compact works collaboratively to share services among six school districts including Kent, Cuyahoga Falls, Hudson, Stow-Munroe Falls, Tallmadge and Woodridge.

Now in its 47th year, The Compact was set up to provide shared educational programs and services (with no added costs to taxpayers). Today, almost 25,000 students across the six school districts participate in rigorous, project-based courses designed to prepare them for college and careers.

Students who choose the CADET Program are required to take four courses during their last two years of high school: Engineering Design, Manufacturing Operations, Machine Tools and CNC Programming for Industrial Mills and Lathes.

During their first year (Level 1), there is heavy emphasis on design and basic machining for the high school juniors. Students also learn G-code manually (also a requirement of Ohio state-designed curriculum). At the end of the year, they must take - and pass - four web-based exams.

The following year (Level 2) as seniors, they learn more about CNC programming, the manufacturing process and project management. "By that time, students have an understanding of why the geometry, why certain materials and so forth," Spear said. They are expected to design and make their own projects and, at that point, students also have the opportunity to go out and work.

"We are not teaching just machining, or just CAD, or just welding," said Jeff Bee, CADET Level II Instructor. "In our program, kids are getting exposure to a lot of different fields. They get a chance to experience a little bit of everything. Typically, there is one student in the class who wants to do industrial design, someone else who wants to do programming, another who thinks, `I really like CAD.' And still another student who prefers machine operating."

"When you look at our program, it is really the old school career-tech way of teaching," said Spear. "All four courses are taught over the two years together - we do not really divide them up into individual portions like a college-type approach. We believe they all work together."

The students' lab is very unique, compared with other high school Career Technical Education programs, according to Bee. "It is not a true machine shop, but more like an advanced manufacturing center," he said.

From the very beginning, the first tool he introduces to students is the waterjet "within four steps, they are cutting something already and they see the impact right away," said Bee. "After that, we can get them involved with other technologies."

Both Spear and Bee said they continuously stress the importance of learning the basics. They familiarize the students with all of the tools in the lab, including the manual ones. Spear said, "A student will walk up to a Bridgeport or to a lathe and say, `I know what this does and I can translate those skills to a CNC.' At that point, we make the connection: That is the X-axis and that is a Z-axis."

Spear noted that, especially when teaching students how to execute a design, foundational knowledge, like G-code, is just as critical as familiarization with drawing software products.

For day-to-day CNC programming, CADET teaches Mastercam 2019 (CNC Software, Tolland CT). "As powerful as Mastercam is, we find it ideal for CAD/CAM education," Spear said. "It has everything we need to help us prepare today's students for tomorrow's challenges."

Spear said that Mastercam use within CADET began just a couple of years ago. "We were actually using another CAM software with most of our lathes and machines, except for our new Haas ST-10 machine, which used Mastercam 2019 Mill-Turn." But, Spear said, CADET was not getting the support and the instruction it needed from the other CAM package. He reached out to Kevin Richardson from Mastercam Reseller FASTech Inc., (Findlay, OH). And the rest, he said, is history.

Richardson sat down with Spear and showed him Mastercam 2019 Mill-Turn. Then, he showed both CADET instructors Mastercam 2019 Lathe, and demonstrated the simple dragging feature in Mastercam's Model Prep feature, which is found in both Mill-Turn and Lathe. Model Prep allows the programmer to create a solid model within the CAM software and manipulate it as needed to add or remove holds, adjust dimensions or diameters, etc. "We were both really impressed with the simplicity of the process," Spear said. "At that point, we were all in."

Bee said he appreciates the attention and support CADET gets from FASTech. "These guys take control of the computer and we figure things out together on speaker phone. It is wonderful to have somebody on the other end."

In education," he added, "it is different than in business. We come up with some quirky and outlandish questions because the kids will do something on the software and we do not know how they did it. So we need someone to help us. It is great having a partner who realizes the importance of `teaching the teachers' so that we are confident when we are questioned by the students."

This year, 22 students are enrolled in the CADET Program (14 in Level 1 and eight in Level 2). Of that total, six are female students, representing a percentage that, Spear said, continues to increase year after year. In fact, two of the female students, Marielle Muncy and Audrey Hepler, are doing their capstone projects with CADET. Capstone projects are done in a student's senior year. They are interdisciplinary, usually requiring students to apply skills across several different subject areas, encouraging them to think critically, solve challenging problems and develop skills that help prepare them for college, modern careers and adult life.

"I have always been interested in how things work - from start to finish," said Marielle Muncy, who is studying CAM Manufacturing. "I love making my ideas come to life." Muncy is currently considering Architectural Engineering or Mechanical Engineering programs at colleges in Ohio.

For Audrey Hepler, the CADET Program has fueled her interest in design. Her intent is to major in Industrial Design at either the Cleveland Institute of Art or The University of Cincinnati. Highlighting another example of a positive outcome from Kent Roosevelt's CADET Program, Spear detailed a venture in which his students not only design and make products, but they sell them as well - to a local vendor that sells wooden Greek letters to sororities at nearby Kent State University.

"Making the letters is the students' hands-on introduction to CNC. They take a drawing - a DWG file - bring it into Mastercam, scale it, learn to put a toolpath to it, and nest it," Spear said. "Within an hour, we can have it on the machine, material already mic'd, then nest and make the G-code. Once the students learn how to read the G-code, they can write it. So they see the whole progression." Once made, the students "finish" the Greek Letter products and prepare them for delivery to their customer.

"From there, students go on to use Mastercam Lathe or Mastercam Mill, becoming familiar with different axes and different machines. The goal is to help the students learn to integrate the software to the machine and make something that actually works so that they can say, "I did that." Spear calls it a classic win-win, with the students now producing the Greek letters at a fraction of the cost of what the company was buying them for before.

Both instructors, Troy Spear and Jeff Bee, lead students on visits to local industrial partners, where they observe real-world activity and engage in discussions on topics like the "Green" initiative, the "Lean" initiative, as well as see the manufacturing processes they have learned about. Spear also helps with the Stanton Middle School STEM Club. He introduced the software to the students in November 2018, and will continue working with them in the use of Mastercam to aid in their understanding of the manufacturing processes.

"We strive to keep the Program current and relevant. Students benefit tremendously from learning about what industry is doing now. For many of them, it is where a lot of things come together," Spear said.

For more information contact:

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com

Kent Theodore Roosevelt High School

1400 N Mantua Street

Kent, OH 44240

330-676-8700