Stratasys' advanced metals platform combines the power of additive manufacturing with short-run metals parts production.

The Stratasys metals platform incorporates the company's proprietary jetting technology and commonly-used powder metallurgy, starting with offering aluminum powders.

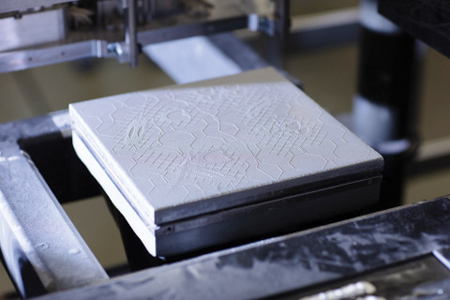

Helping customers pioneer a new era in additive manufacturing (AM) for production-grade metal parts, Stratasys has released further details of its new platform currently being developed and designed for short-run metal applications. "First unveiled in 2018, the additive platform is based on Stratasys' innovative, first-of-its-kind Layered Powder Metallurgy (LPM) technology, designed to make production of metal parts quicker, easier and more cost-effective than ever before," said a company spokesperson.

Intended to disrupt conventional manufacturing approaches, the advanced platform is being developed to combine the value of AM with short-run metal parts production. The innovative technology is built to drive improved efficiency and cost savings using standard Powder Metallurgy (PM) alloys, mechanical properties with high accuracy and controlled shrinkage, as well as fast throughput.

"Current approaches to 3-D printing metal parts leave a lot to be desired - including slow post-processing, painstakingly intricate support removal and hours of matching and grinding. Combined with the high cost of AM powders, this means each part is expensive, with a total cost of ownership that is hard to justify," said Rafie Grinvald, Director of Product Marketing and Management, Stratasys. "Our new platform is being designed to transform the current metals AM landscape - presenting a viable alternative to typical production methods - and helping customers dramatically reduce the costs of creating reliable, consistent production-grade, metal parts for short-run applications."

Developed internally over the past several years, Stratasys' platform incorporates the company's proprietary jetting technology and commonly-used powder metallurgy, starting with offering aluminum powders. The LPM solution includes a 3-step, AM process combining traditional powder metallurgy with Stratasys' PolyJet ink-jet technology. The process includes printing of boundaries with proprietary thermal ink, powder dispensing and spreading and then compaction of the powder layer to achieve high-density and controllable shrinkage.

The end result is intended to be economically competitive in regards to cost-per-part and throughput with easy to implement post-processing and high part quality. The system aims to directly address needs of customers who require production of pilot-series parts, small-batch manufacturing during product ramp-up and end-of-life, as well as customized, lightweight, complex parts. The offering is suitable for automotive, aerospace and defense markets.

For more information contact:

Stratasys Ltd.

7665 Commerce Way

Eden Prairie, MN 55344

877-489-9449 / 952-937-3000

info@stratasys.com

www.stratasys.com