Zero-Touch, the recently patented DWFritz 3-D multi-sensor coordinate metrology platform.

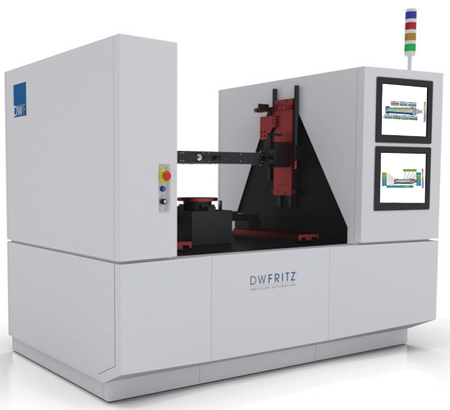

Zero-Touch, the recently patented DWFritz non-contact multipurpose metrology platform without the microenvironment option.

DWFritz Automation, a provider of high precision automation, offers its DWFritz Metrology line products. Zero-Touch is a recently patented non-contact multipurpose metrology platform. AMP 3100 is an automated high-speed non-contact metrology system suitable for 100% inspection of precision small parts. The Defect Detection System is a deep learning-based flexible inspection system that identifies surface imperfections on any material with speed, reliability and precision.

"Zero-Touch is a highly configurable system that simultaneously captures multiple 3-D measurements in a fraction of time compared to traditional CMMs," said a company spokesperson. Zero-Touch measures part features and complex geometries such as bores, undercuts and chamfers, in addition to complex surface topology, such as surface finish, color and gloss. "It features a rotating bridge 5-axis metrology platform that can achieve part inspection speeds up to 10 times faster than conventional tactile CMMs," added the spokesperson. A unique bridge rotation uses multiple non-contact measuring sensors including optical, laser line scanner and confocal technologies. Seamless Zero-Touch CAD-based measuring software provides easy generation of part measurement plans using motion path creation, simulation and sensor parameter settings with no specialized programming required. The part's generated 3-D point cloud is transmitted to Innovmetric's Polyworks analysis software, creating a detailed inspection report with actionable information for improving manufacturing processes.

AMP 3100 is an automated high-speed non-contact inspection system that features a state-of-the-art machine vision system, lasers, custom lighting and advanced robotics. The system captures dimensional and angular measurements and 3-D profiles, cosmetic features and color and gloss measurements for SPC, process optimization and integration with Manufacturing Execution Systems (MES). With its high throughput capabilities, AMP 3100 can achieve processing speeds that exceed four parts per second, making the system suitable for in-line manufacturing applications.

DWFritz's Defect Detection System is a flexible inspection system that combines machine vision with deep learning algorithms suitable for surface detection defects for glossy, shiny or rough surfaces. "While traditional machine vision systems use complex rules-based algorithms and require precise defect definitions, the deep learning software learns from images of good and bad parts, reducing the time needed to specify defects and respond to changing requirements. Combined with advanced robotics, custom multispectral lighting and custom fixturing, the Defect Detection System helps manufacturing improve product quality of part surfaces," said the spokesperson.

For more information contact:

DWFritz Automation, Inc.

9600 SW Beckman Road

Wilsonville, OR 97070

503-682-4757

www.DWFritz.com