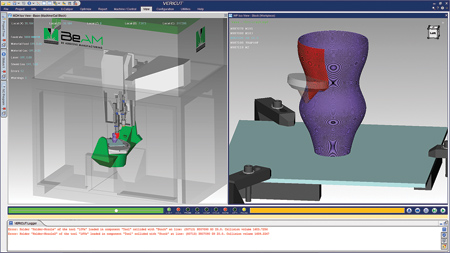

VERICUT simulation, driven by the same G-code data that will run on the BeAM machine, safeguards against dangerous and expensive mishaps like this "Rapid" plunge into the additive part.

Additive manufacturing (AM) solution provider BeAM has joined forces with CGTech, a provider of CNC simulation and optimization software, for help with verifying the millions of lines of code needed to drive its 3-D printers.

BeAM's powder-based Deposition (DED) technology utilizes a high-powered laser and coaxial deposition nozzle to apply highly accurate, 3-D layers of aerospace grade materials like titanium, Inconel, stainless steels and more.

BeAM's DED can be used to repair parts like turbine blades and fuel nozzles, add features to existing geometries and build near net shape with high quality surface "Not only is the machine extremely accurate, but having 5-axis brings a great deal of flexibility to the table," said Austin Kron, Business Development Manager from BeAM's North American operations. "For example, we can generate part features less than one millimeter thick, with better than 100 microns accuracy. This eliminates much of the post-process machining needed with virtually all metal parts. And unlike powder bed machines, we do not need support structures during the build-we just rotate the part to whatever orientation is necessary to maintain proper geometry."

These 5-axis capabilities allow BeAM machine users to take design freedom in ever more complex directions. However, even with the ability to create previously unachievable shapes, the BeAM has found visualization of these shapes increasingly challenging. That is why the team at BeAM's Cincinnati, OH, solutions center turned to toolpath simulation provider CGTech Inc. for help with verifying the millions of lines of code needed to drive its 3-D printers.

CGTech's VERICUT Additive module is the latest in a series of software tools designed to make manufacturers more efficient and their equipment safer. With the ability to simulate all aspects of the 3-D printing process, VERICUT can:

- Eliminate expensive machine downtime and scrapped workpieces by detecting collisions before they happen

- Validate machine operating parameters such as gas flow, laser wattage and proper material flow per material type

- Maintain the entire part build history for troubleshooting purposes, or for customer-mandated archiving

- Clearly identify programming errors as well as opportunities for process improvement.

- Provide realistic viewing of the additive process, part build from it and machine tool motion throughout the build process, long before the laser lights up or the powder begins to flow.

The software does all this by reading the same G-code data file that the machine uses. There are never translation errors, and it does not matter where the code came from, whether it was generated by a CAM system, a custom application, text editor or composite from any of these means.

"VERICUT Additive uses a digital twin of the workpiece and machine tool to simulate 3-D printing and hybrid processes," said CGTech Product Manager Gene Granata. "Because VERICUT sees what the machine sees, it creates a layer of machine protection and simulation accuracy otherwise impossible to achieve. This is especially important with high-speed 5-axis machine tools like BeAM's, due to the extreme part complexity and fast build rates made possible by its equipment. This is why we have become technology partners."

Tim Bell, Engineering Director at BeAM, agreed: "VERICUT Additive has proven to be an extremely valuable tool for optimizing code. It has certainly reduced the amount of time needed for process development, and its simulation capabilities have helped us detect and avoid costly collisions. It can also be used for calculating cycle times in advance of the actual build, determining part feasibility and giving us greater confidence with difficult geometries. I would strongly recommend VERICUT to any of our customers."

For more information contact:

CGTech

9000 Research Drive

Irvine, CA 92618

949-753-1050

info@cgtech.com

www.cgtech.com

BeAM

5101 Creek Road

Cincinnati, OH 45242

513-745-4510

usa@beam-machines.com

www.beam-machines.com