All-Electric Tube Bender

April 1, 2017

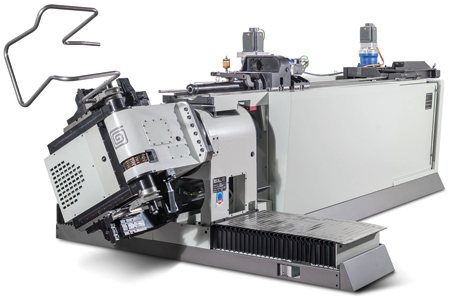

BLM GROUP USA Model E-TURN all-electric tube bender

E-TURN, the all-electric tube bender from BLM GROUP USA, can bend a variety of tube configurations including round, square, rectangular, flat-sided, oval and elliptical. Tube can be automatically loaded, bent and unloaded all in one machine. The E-TURN provides right and left hand bending in an automatic cycle.

The series consists of four models: The E-TURN 32 that can handle tube sizes up to 1.18" dia.; the E-TURN 35 that handles tube up to 1.38" dia.; the E-TURN 40 for tube up to 1.63" dia. and the E-TURN 52 for tube up to 2.0" dia. The standard maximum bending radius is 6.5" and can be increased if the need arises. The bend head incorporates a direct gear-box drive which eliminates backlash.

The precise control and positioning of the all-electric axes provides for working parameters that can be reproduced the first time, every time.

Because of the E-TURN flexibility, accuracy and speed it is suited for the furniture, pipe and automotive industries as well as for job shops. It is environmentally friendly with low noise levels, no hydraulic oils, no leaks and no filter replacement.

The E-TURN Series is designed with easy-to-use VGP3D software with advanced 3-D graphical programming. By simply inputting the component's bend coordinates the software can quickly provide users with real-time simulation of the bending operation and automatically correct for possible collision points. The software also permits off-line programming for high degrees of both automation and production planning.

For more information contact:

BLM GROUP USA

29380 Beck Road

Wixom, MI 48393

248-560-0080

sales@blmgroupusa.com

www.blmgroup.com

< back