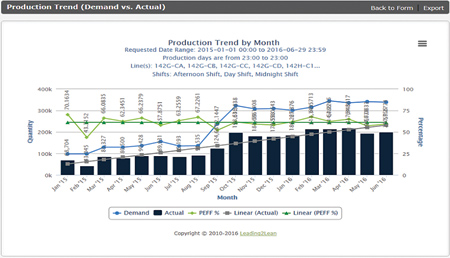

"Data collected by BorgWarner through Leading2Lean's CloudDISPATCH supported a significant product demand increase with virtually no impact to process efficiencies," said a company spokesperson.

Leading2Lean CloudDISPATCH software is easy to read and intuitive.

Cloud-based lean manufacturing solution provider Leading2Lean was part of a total productive maintenance (TPM) solution that helped auto powertrain maker BorgWarner increase overall equipment effectiveness (OEE) of an operating area by 10% in six months, when coupled with its TPM implementation, at BorgWarner's Seneca, SC, plant.

Within a short time period after implementing Leading2Lean, the plant began to resolve inefficiencies and frustrations with the new system that allowed them to better identify production weaknesses. The plant was soon able to handle an increase in product demand while still improving first pass yield ratios, reducing scrap, maintaining high production levels, better utilizing labor resources and improving overall communication with management and employees. The team maintained high levels of operational availability - some areas as high as 90%.

Area employees drive this process optimization - scheduling, planning and monitoring performance of machines on their lines - all through the Leading2Lean product. "It is as easy to use as Facebook or Google," said Will Venet, TPM Implementation Leader at BorgWarner.

Experienced managers also find the system intuitive. "What a reliability engineer took decades of experience to learn can be learned in an afternoon," Venet said.

Plant Maintenance Engineer Rodney Osborne said the crew used to use "gut checks" to guess which machine needed maintenance or how much money they spent on spare parts for a machine.

"Now with Leading2Lean, we do a simple report and it tells us - there is no ambiguity," Osborne said. "It takes the gut check out of it. It is real data, and it is without question a much better way of doing business for us."

"Initially, some employees thought bringing in the Leading2Lean system was an oversight effort, like `Big Brother,' but results soon changed their minds," said a BorgWarner spokesperson. "Today, there is a far more collaborative relationship between production and maintenance, and team members at all levels feel more engaged because they are empowered to identify and produce solutions for continuous improvement."

Downtime reductions were driven largely by the engagement of operators. This was because they had easy access to the data and the manipulation of that data to drive improvements in preventative maintenance. What used to take four or five days to analyze through laborious data mining can now be done in 20 minutes.

"The collaborative efforts the team is making for continuous improvement are influenced by having a tool that is universally appreciated," Venet said. "I have come to appreciate that what Leading2Lean is really doing is helping us to be a better manufacturer all around."

Leading2Lean cloud-based systems are designed to provide critical real-time information to help rank-and-file workers do their jobs better and take ownership of their work. "A better-focused and motivated workforce produces more and of better quality, and leads to habits of continuous improvement," said a company spokesperson.

For more information contact:

BorgWarner

15545 Wells Highway

Seneca, SC 29678

864-985-0568

www.borgwarner.com

Leading2Lean

88 Deer Pass Road

Wellington, NV 89444

877-225-5201

sales@leading2lean.com

www.leading2lean.com