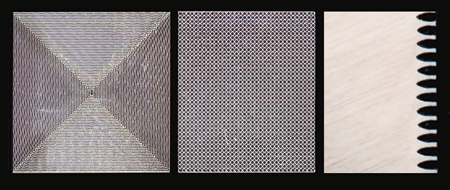

Laser texturing can be used to create patterns based on blind holes from a few micrometers diameter and depth (left and center) to a few tenths of a millimeter diameter and depth (right).

Laser surface texturing with LASERDYNE 795 and 430 BeamDirector multi-axis laser systems is another process capability of these flexible, precision 3-D laser processing systems as their applications expand. "With the precision and flexibility of these systems, texturing, like other applications, is accurate and easy to perform," said a company spokesperson.

Laser texturing with a LASERDYNE system is effectively another type of laser drilling process that involves producing "blind", or partial depth, holes and indentations from a few micrometers to a few tenths of millimeter in depth. This process is currently used to form precise and detailed textures on the surface of metals. For this reason, the use of a laser for texturing is rapidly growing in automotive, medical device and moldmaking industries, just to name a few. In many of these new applications, the laser surface texturing process is becoming an integral part of the product design process.

A feature of LASERDYNE laser texturing is that it is suited to three dimensional (3-D) surfaces. Programming and process development are simplified with features of the LASERDYNE S94P Laser Process Control such as CylPerf Cylinder Perforation Programming and Process Control and LinPerf Linear Perforation Programming and Process Control. "Both CylPerf and LinPerf provide an easy way to program and visualize macro programming blocks that create complex rows of features on cylindrical and flat surfaces, respectively," said the spokesperson.

On-the-fly processing has been used for drilling small diameter holes and now features that create unique textures. The process makes use of the latest fiber laser technology and advanced control of laser parameters through the LASERDYNE S94P and can be applied to virtually all metals and alloys, including mold steel, stainless steel and titanium, as well as a number of plastics that absorb the laser beam.

Laser Surface Texturing Compared to Other Texturing Methods

The capability of 3-D laser texturing is based on the same characteristics of laser processing as for other applications. For example, compared to mechanical processes, laser texturing does not require specialized tools (drills) and involves no tool wear or breakage. The ability to focus the laser beam to small diameters creates the possibility for smaller features than can be produced by mechanical methods.

Compared to chemical processes, laser texturing does not involve toxic and corrosive chemicals used in the chemical etching process that can have a negative environmental impact as well as pose harmful operator exposure problems. Also, laser texturing does not require tooling (artwork) to define the pattern because the texture detail is created by the laser beam.

"An additional benefit of LASERDYNE laser texturing using 795 and 430BD systems is that these systems have capability for high speed, precise cutting, welding and drilling," said the spokesperson. "These capabilities - all in one machine with the appropriate laser source - can reduce part handling, simplify operation, and save capital expense and floor space required for machines dedicated to a single process."

For more information contact:

Prima Power Laserdyne

8600 109th Ave. North, #400

Champlin, MN 55316

763-433-3700

lds.sales@primapower.com

www.primapower.com