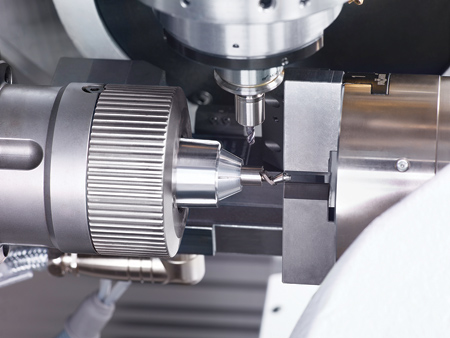

The swivel-head axis is aligned with the tool center point for accuracy during simultaneous machining. This eliminates the need for compensatory movement in the milling axis.

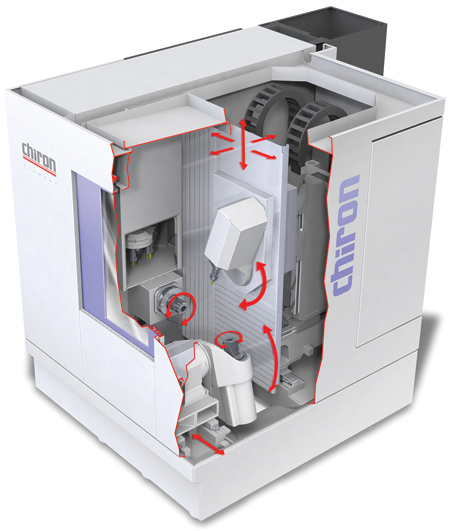

CHIRON America, Inc. has introduced the FZ08MT Precision+ Machining Center featuring complete, six-sided precision machining within a small footprint. "Developed as a flexible, ready-made solution for manufacturers with demanding tolerances and quality requirements, the Precision+ can achieve flawless surfaces with speed and efficiency," said a company spokesperson. "Even complex 5-axis parts can be produced in a single set-up without the need for additional finishing. With thermal stability and rigidity, along with chip handling, the FZ08MT Precision+ can remain flexible whether manufacturing small or large production volumes."

Featuring a primary swivel-head spindle, full-fledged turning spindle and a counter spindle for reverse-turning or simultaneous 5-axis machining, the FZ08MT Precision+ consolidates multiple tasks into one compact unit (milling, turning, drilling, threading, etc.). The main spindle incorporates a direct torque drive with a swivel range of -10° up to +100°, delivering speeds of up to 54,000 RPM. Designed for increased dynamics and rigidity, the swivel head performs with accuracy helping to ensure the tool center point remains constant, without movement in the X and Z axes. Additionally, full-value turning up to 8,000 RPM can be achieved with the turning spindle, which accommodates bar diameters up to 42 mm. The integrated counter spindle allows simultaneous 5-axis work during the machining process.

With travel paths (X-Y-Z) of 210 mm, 200 mm and 360 mm, the FZ08MT Precision+ provides numerous application possibilities, while the machine's footprint of 33.3 sq. ft. offers floor-space benefits. An additional new CHIRON design feature is the tool changer with a chip-to-chip time of approximately 2.1 seconds. Capable of holding up to 96 tools, the operator has the added flexibility of utilizing the machine's loading gate to exchange tools during production.

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info@chironamerica.com

www.chironamerica.com

IMTS 2016 Booth S-9066