Creating the foundation for smart factories with ZOLLER datatransfer using »roboSet«

Professional entry-level tool presetting with the new »pilot 1.0« image processing

»reGrind«, a new regrinding module for »pomBasic«

The smart automation solution, »roboSet 2«, is now capable of covering even larger series in unmanned quality assurance or production processes.

Scan the QR code with »zidCode« and the data is automatically transferred to the machine

Efficient management and measurement of grinding wheels is now possible using the new grinding wheel management package for ZOLLER TMS Tool Management Solutions

Turning Advisor helps to save time during turning and milling machining operations

»digitalTwin« is a new software module for "smart manufacturing"

ZOLLER will present its product range, from tool presetting, measuring, inspection and automation to software solutions at IMTS 2016.

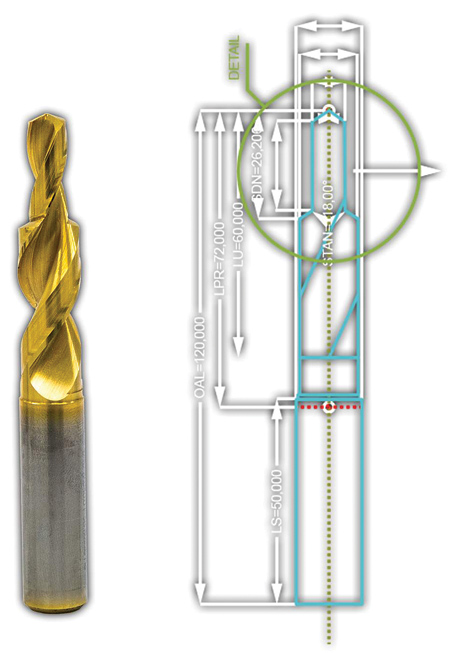

Modern tools have achieved a high level of performance and precision. Only correctly set and measured tools can be used. That calls for correspondingly high-precision inspection and measurement. Particularly with complex tools, precise tool setting is essential. In this process, ZOLLER assists with presetting and measuring devices that are custom-built to suit a variety of types and sizes of tools.

"All ZOLLER systems satisfy the increasing requirements regarding 100% inspection, gapless documentation and traceability, regardless of the solution employed," said a company spokesperson. This forms the basis for smart manufacturing: the consolidation of all tool data in a centralized database, process-reliable data exchange between machines and, using the automation solution »roboSet«, the option to fully automate quality assurance.

Premieres at IMTS 2016 include:

Presetting Solutions

The new image processing technology »pilot 1.0« offers functions for presetting and measuring standard tools quickly and easily. These include, automatic cutter shape and measuring range detection, navigation system »compass«, projector function and cutting edge inspection, »cris360°« to determine the effective cutting area of tools and a clear representation of the tool cutting edge on a 13.3" panel PC.

The ZOLLER tool presetter »smile« with »pilot 1.0« can be used on the shop floor next to CNC machines in processing and test centers or in measurement rooms. "Features include easy operation, real time presentation of the measurement results in the camera field of vision, and a workshop-compatible device version," said the spokesperson. All standard measuring functions are available, including longitudinal and cross dimensions, radius, two-angle technology and concentricity and run-out.

Inspection Solutions

»reGrind«, the new ZOLLER software module for wear measurements, enables economical regrinding processes. Due to this new regrinding module, »pomBasic« can now also be used as an electronic caliper gauge for precision tools to be reground.

The tools are checked for wear and their dimensions are measured prior to the grinding process. This is done in a user-guided manner, which makes it fast and safe. The wear characteristics determined this way are allocated to a corresponding pallet location and thus form the basis for machining during the regrinding process. Due to the data exchange with the grinding machine, data no longer has to be entered in the controller manually - helping to enable fast, process-reliable and error-free transmission. "The fact that regrinding is henceforth only done as required by actual wear saves time and money while maximizing tool service life," said the spokesperson.

Automation Solutions

The version »roboSet 2« of the smart automation solution for tool measurement »roboSet« now features a more compact and space-saving design. Furthermore, it can be coupled with the universal measuring machines »genius« or »titan« and fitted with laser or ultrasound cleaning upon request. Due to a multi pallet system and the associated larger number of tools, this smart automation solution is now capable of covering even larger series in unmanned quality assurance or production processes, while its new double gripper makes it faster.

Software Solutions

The ZOLLER identification code, »zidCode«, is a new and efficient solution for tool identification and data transfer for small to middle sized companies. The procedure of this data transfer version, which does not need a network connection, is simple: the tools are measured by the ZOLLER presetting and measuring device. The measured tool data is encoded in a QR code, which is printed on a label. The QR code is scanned with the reader, and the data is automatically transferred to the control of the CNC machine. Manual data entry and typing errors can therefore be eliminated.

The new grinding wheel management package enables systematic and efficient management as well as measurement of grinding wheels. This ensures not only precise measurements but also seamless provision of grinding wheel data required in the manufacturing process. The ZOLLER »elephant« technology for grinding wheels enables fully automatic measuring of entire FEPA grinding wheel packages at the push of a button by scanning the 3-D contour without any data input. This process measures grinding wheel parameters such as diameter, angle, flange offset and corner radius and clearly displays them in the input dialog of the »pilot 3.0« image processing measuring program. The structure of a grinding wheel package is reproducibly documented in a parts list. Measurement macros for the individual grinding wheel types according to the FEPA standard are included by default. Availability is visible at any time due to connected storage systems.

The new Turning Advisor software function makes it possible to define on turning-milling machines different tool positions with measuring adapters, installation situations with counting directions and cutting edge positions. This prevents the need for countless adapters being set up on the tool presetter and measuring device in order to suit every situation on the turning machine.

Users of ZOLLER products are well-equipped for future developments. "For smart manufacturing to reach the shop floor, manufacturing plants not only need top-notch physical tools in the machines but also their digital twins for work preparation," said the spokesperson. Therefore, ZOLLER does not only offer solutions for 100% inspection and documentation of physical tools, but also solutions for generating digital twins according to DIN 4000 with the new software module »digitalTwin«. "This enables tool manufacturers as well as grinding and sharpening companies to offer customers added value, while ensuring they are prepared for the requirements of tomorrow," said the spokesperson.

For more information contact:

Zoller Inc.

3753 Plaza Drive

Ann Arbor, MI 48108

734-332-4851

sales@zoller-usa.com

www.zoller-usa.com

IMTS 2016 Booth W-2022