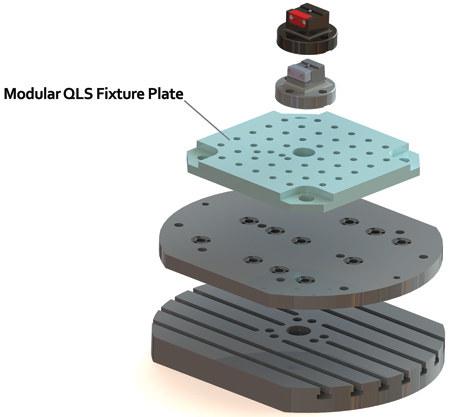

Modular Fixture Plate With Quick Change Connection

August 1, 2016

The new QLS fixture plate from Jergens is engineered to connect with Ball-Lock, allowing users to add the Fixture-Pro system of top tooling options.

Jergens Inc. will demonstrate its new Quick Locating System (QLS) Fixture Plate designed for use with the company's Ball-Lock quick change system. With the connection to Ball-Lock, the QLS allows users to add the whole range of the Fixture-Pro system.

"The ability to use the Fixture-Pro range extends the machining envelope on five axis machines," said Steve Schmidtke, Group Manager for Jergens Workholding Solutions Group. "The modular workholding of Fixture-Pro combined with the quick and accurate location of Ball-Lock provides a multiplying effect on productivity." The concept has been designed to offer users a system that could be changed over, even between machines, in seconds. Ball-Lock sub plates mount directly to the machine table and provide the connection to the new QLS system, which in turn connects to a range of combinations of Fixture-Pro risers, adapters and top tooling.

For more information contact:

Jergens, Inc.

15700 S. Waterloo Rd.

Cleveland, OH 44110-3898

877-486-1454

info@jergensinc.com

www.jergensinc.com

IMTS 2016 Booth W-2154

< back