The new Postcheck feature of VERICUT CNC Machine Connectivity software allows programmers to document and verify actual jobs at any time and location to increase productivity and program accuracy.

Shop Floor Automations (SFA), a manufacturing integrator specializing in digitally transformative hardware, software and support solutions, will demonstrate the new Postcheck feature of the VERICUT CNC Machine Connectivity software at IMTS 2024.

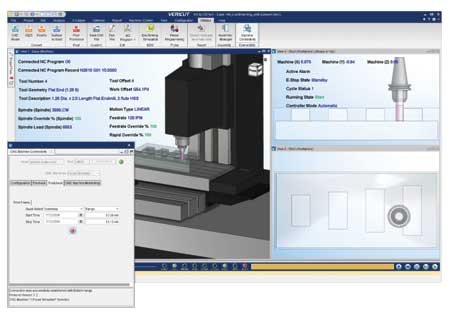

This feature of CNC Machine Connectivity, which utilizes the Scytec DataXchange machine monitoring solution, supports the analysis of digital twin simulations through the replay of stored, live-streamed data from the numerical control (NC) machine. Through such replays, Postcheck allows programmers to retrieve archived data from when a part was machined, then rerun that data in VERICUT to investigate issues that may have occurred during the machining process.

The VERICUT CNC Machine Connectivity modules were launched as an add-on to the 9.3 release of VERICUT software in 2022 through a partnership between CGTech and Scytec Consulting Inc. CNC Machine Connectivity aligns digital twin simulations of CNC programs and live production to enable manufacturers to detect, communicate and validate variances in order to produce higher quality parts at faster rates.

"After verifying NC programs and sending them to the shop floor, NC programmers frequently lose visibility into what happened with those programs in the shop," said Gene Granata, CGTech Director of Product Management. "When asking the machine operator or shop foreman about the performance of the NC programs and any necessary changes, their responses can be too vague at times to identify how or where modifications were needed. This means the same issues will likely occur the next time the programs run. The Postcheck feature of CNC Machine Connectivity closes the loop on the NC programming process by providing engineers and programmers with access to factually-recorded data about how NC machines and programs ran, including exact spindle or feedrate override percentages or emergency stops that occurred, right at their fingertips."

As a reseller of DataXchange and various CNC hardware and software solutions, SFA president Greg Mercurio understands the opportunity CNC Machine Connectivity offers those involved with NC manufacturing: "This latest feature of CNC Machine Connectivity is yet another example of how today's technology is tightening the processes and relationship between engineering, programming, quality, estimating and the machine shop and tool crib on the floor," said Mercurio. "We are excited to share the range of possibilities with manufacturers at this year's IMTS."

For more information contact:

Shop Floor Automations, Inc.

5360 Jackson Drive, Suite #202

La Mesa, CA 91942

877-611-5825 / 619-461-4000

info@shopfloorautomations.com

www.shopfloorautomations.com

IMTS East Building, Level 3

Booth 133240