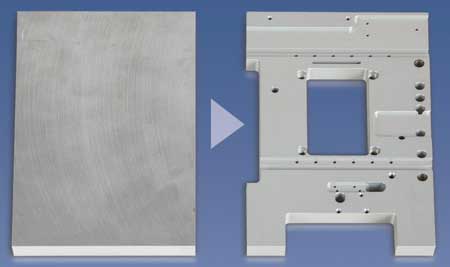

Machine-Ready Blanks (left) from TCI Precision Metals help shops shorten set-up time, reduce scrap and increase overall throughput by up to 25% by eliminating material prep. Machine-Ready Blanks arrive machine-ready for production. Ready-to-ship blanks in low quantities are available for immediate shipping, or custom-made-to-order blanks can be ordered in production quantities with fast turnaround.

TCI Precision Metals will showcase its precision Machine-Ready Blanks capabilities to customers at IMTS 2024.

help shops shorten set-up time, reduce scrap and increase overall throughput by up to 25% by eliminating material prep. They are guaranteed to arrive machine-ready for production, with standard-size blanks in low quantities ready for immediate shipping or custom-made-to-order blanks in production quantities available for quick turnaround.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and individually packaged to avoid damage during shipping. Ready-to-ship blanks can be ordered online for same-day or next-day shipping and arrive square, flat and parallel within ± .002" of specified dimensions all around.

Custom made-to-order blanks are made to customer specifications. They are guaranteed as close as +/- .0005" dimensionally and as close as .0002" flatness, squareness and parallelism.

"Customers can use the time they previously spent in set-up and prep for more productive use of CNC machining centers, adding to their bottom-line profitability. With our ability to consistently produce close tolerance, flat blanks, part movement is reduced, improving overall quality," said Ben Belzer, President of TCI Precision Metals.

For more information contact:

TCI Precision Metals

240 E Rosecrans Ave.

Gardena, CA 90248

800-234-5613 / 310-323-5613

sales@tciprecision.com

www.tciprecision.com

IMTS West Building, Level 3

Booth 432123