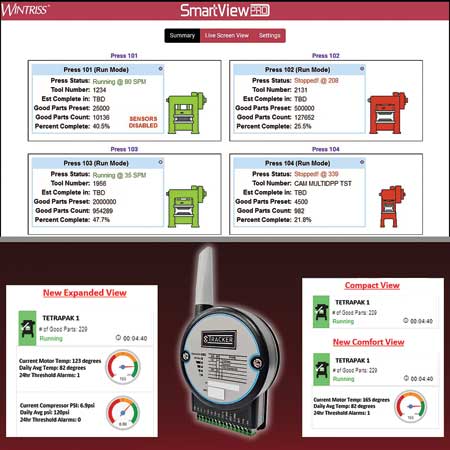

Top: New SmartView PRO network interface

Bottom: SFC ShopFloor Tracker with data examples (size of device is approximately 3" x 6" x 1").

Wintriss Controls Group will be demonstrating a new, advanced interface in its SmartPAC PRO Press Automation Controller and an economical ShopFloor Data Tracking Solution at FABTECH booth S29074. For a connection to a smarter factory, including when remote monitoring is required, the latest functionality in SmartPAC PRO and ShopFloorConnect (SFC) gives fabricators and metalformers efficient and easy-to-use tools to control, automate and track their vital operations.

Wintriss will be introducing the new SmartView PRO Network Interface for its SmartPAC PRO Press Automation Controller. The SmartView PRO Network Interface allows any PC or mobile device on a network to access and download information from networked SmartPAC PRO controls.

The new interface displays the current job status, press tonnage, percent of job complete and estimated time until job completion. Users can also view the SmartPAC PRO's error and event logs, send an on-screen text message to the press operator and download the installed option list, tool list and individual tool programs.

Wintriss will also demonstrate its new, compact SFC ShopFloor Tracker hardware device, an economical way for its ShopFloorConnect software to automatically collect production data from virtually any machine. The SFC Tracker is a wireless machine monitor that can be installed on any machine or production line to track machine parameters such as run time, idle time, production counts, production rate, uptime efficiency, temperature, pressure, humidity and more without requiring any operator input.

"The most outstanding trait of the SFC Tracker is its versatility, featuring four inputs that can be configured to accept input from a variety of digital or analog signals," said a company spokesperson.

In addition to Wintriss' booth presence at the show, Industry Die Protection expert Jim Finnerty of Wintriss will be presenting "Sensors for Die Protection" in Room S06 from 8:30 AM to 10:00 AM, on Wednesday, October 16. Finnerty created the Wintriss Die Protection Clinic for die protection and in-die sensing information and training, which he has led for over 25 years. He will also be available for consultation in the Wintriss booth before and after the presentation.

For more information contact:

Wintriss Controls Group

100 Discovery Way, Unit 110

Acton, MA 01720

800-586-8324

www.wintriss.com

FABTECH Booth S29074