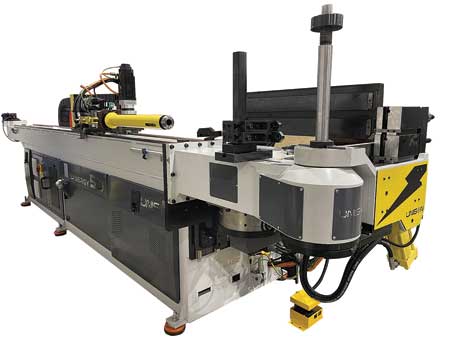

Unison Synergy hybrid-electric tube bending machine

Unison Tube LLC, the North American division of UK-based Unison Ltd, the inventors of all-electric tube manipulation, will be presenting a range of tube and wire-bending technologies at FABTECH.

Visitors to booth S34035 will be able to view one of Unison's recently launched Synergy hybrid-electric tube bending machines, a Unison EvBend 1000 manually operated, CNC-controlled tube bending machine and a Pneuform rotary head wire and tube bending machine.

"FABTECH is always a key event on our calendar," said Stuart Singleton, VP of Unison Tube LLC. "The 2024 event, however, is going to be extra special for us. Not only because 2024 marks the 30th anniversary of Unison Ltd launching the world's first all-electric tube bender, but because it is also the first year we will be showcasing Pneuform wire and small-bore tube bending machines."

A company spokesperson said, "Unison Ltd acquired Pneuform-a leading name in the manufacture of wire forming and small-bore tube bending machines-in the fall of 2023, and has been working hard to ensure the brand continues to lead the way in the wire bending machinery market."

Like all Pneuform machines, the model on show at FABTECH will be equipped with Yaskawa drives and Unison's user-friendly software for easy programming and operation.

Developed to make Unison quality and reliability accessible to even more companies involved in tube manipulation, Unison Synergy hybrid-electric, dual-stack tube bending machines combine precise electric control with advanced, near-silent operation.

"Our Synergy models have proved highly popular with manufacturers and subcontractors who carry out repetitive tube bending tasks," said Singleton. "As well as the 50 mm model we will have on show, there is also a larger 80 mm machine. Both have our user-friendly Unibend control and industry leading motors and drives. They offer exceptional power and rigid mechanical design."

Finally, visitors to Unison's booth will be able to discover the company's EvBend machines.

"Designed for low volume, high-accuracy production and prototyping, Unison EvBend models are used across the aerospace, MRO, Formula 1 and oil & gas industries, where they provide CNC-controlled, manually operated 3-axis mandrel, multiplane bending at a fraction of the cost of fully automated machines," said the spokesperson.

While the EvBend 1000 has been designed for bending tube of up to 16 mm in diameter (22 mm in copper), a larger machine, the EvBend 2000, is also available. Built to bend tube of up to 50 mm in diameter, its bending function is servo-assisted.

"Add the latest advances in Unison's Unibend CNC, tube bending simulation software and advanced tube bending application app, and we have a good deal to show customers old and new," concluded Singleton.

For more information contact:

Unison Tube LLC

240 Eastwood Drive

Danville, VA 24540

828-808-4286

sales@unisonltd.com

www.unisonltd.com

FABTECH Booth S34035