The INDEX MS22-6L as a front-opening machine offers easy accessibility.

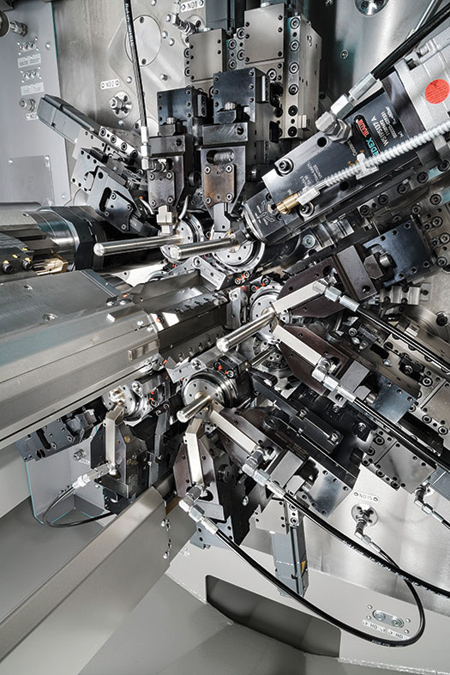

The typical INDEX arrangement of tool carriers in the working area allows more than one tool to be used on each spindle.

INDEX-group, with the MS22-6L, offers a Swiss-type turning unit version of a CNC multi-spindle automatic lathe. "The development team has succeeded in adding a Swiss-type turning unit to the tried and tested MS22-6, retaining all the typical advantages of INDEX multi-spindle machines," said a company spokesperson. Thus, the workpiece can be pre- and finish-turned simultaneously in one spindle position.

"With certain combinations of component size, complexity and quantity, CNC-controlled multi-spindle machines are by far the most efficient solution," continued the spokesperson. "However, this statement did not apply previously to long and narrow turned parts, for which an unfavorable ratio of length to diameter made precise machining impossible," said a company spokesperson. "For typical long turned parts in high quantities, users only had the option of using a number of single-spindle sliding headstock machines. The newly developed Swiss-type turning unit was first adapted to an INDEX MS22-6. It can be used to machine long turned parts up to a length of 200 mm and a bar diameter of 5 mm to 22 mm. In particular, manufacturers of series production parts, such as injection nozzles for internal combustion engines or nozzles and pistons in fluid technology, as well as implants in dental technology, should profit from this. But in the near future, this will include also producers of electric drives who will be provided with highly productive equipment for the production of a wide variety of shafts. These are in general typical mass production parts in which traditional sliding headstock turning machines are at a disadvantage due to reduced efficiency."

The core of the Swiss-type turning unit is the centered guide block on which six long turning sleeves are moving. The ball-bearing guide bushing unit is equipped with a double-cone guide clamp.

In order to achieve best results with different machining operations, the guide bushing can be programmed with different guide pressures. For milling, the guide clamp is attached firmly to the bar stock. In addition, a built-in swiveling synchronized spindle not only ensures damage-free removal of the finished components, but also enables rear-side machining on three tools.

"The MS22-6L is the world's first multi-spindle turning machine that allows simultaneous use of two tool carriers per spindle position for sliding headstock machining with six spindles," said the spokesperson. The resulting 12 tools in use offer a high level of productivity. In addition, the slideways in INDEX technology on guide and machining slides provide increased rigidity and, as a result, more precision. The swiveling synchronized spindle allows rear end machining with three tools, while the use of live tools enables milling operations.

"Apart from the Swiss-type turning unit, the MS22-6L is a genuine MS22-6. All tools of a normal MS 22 can be used and all peripherals of the basic machine can be adopted," said the spokesperson.

There are 62 NC axes available to the user for machining complex parts. But this not only ensures the machining of complicated contours. This configuration also allows a wide scope for the use of different methods and enables the necessary variable use of the tool carriers. "As a result, the user is on the safe side even with difficult to machine workpieces. Especially as the Siemens Sinumerik 840D solution line stands for innovative control technology," said the spokesperson.

The machine design of the MS22-6 - a front-opening machine for bar machining - offers easy accessibility, while providing the user with live tools, C and Y axes to allow a wide range of machining options, such as off-center drilling and threading, contouring and hobbing or polygonal turning. The central module consists of six air-cooled motorized spindles integrated into the spindle drum, with three-part Hirth coupling for precise positioning of the spindle drum. Always the optimum speed is available during machining for each spindle position and cutting tool edge. "The results are optimum chipping, maximum surface quality, short production times per piece and extended tool life," said the spokesperson.

The typical INDEX arrangement of tool carriers in the working area allows more than one tool to be used on each spindle. The possible machining operation is thus limited only by the toolholder. As a result, the user can specify all production steps in almost all spindle positions.

"One INDEX MS22-6L usually achieves a part output like up to six single-spindle CNC sliding headstock automatic lathes with multi-spindle technology, which the customer only needs one handling, and one coolant preparation, saves energy and requires fewer personnel," concluded the spokesperson.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.index-usa.com

SOUTHWEST

TX

Prosper Machine Tools, LLC

7415 Whitehall Street, Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

NM

AME, Inc. (Adv. Mfg. Eng., Inc.)

5770 Clarkson Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AR, LA

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

SOUTHEAST

NC, SC, VA

Advance Machinery Sales, Inc.

416-C Gallimore Dairy Rd.

Greensboro, NC 27409

336-665-9114

TN, AL, MS, FL (Panhandle)

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

NORTHEAST

N. NY

Britton Machinery Sales

330 Castlebar Road

Rochester, NY 14610

585-721-4160

MA, CT, RI, ME, NH, VT

High Performance Machinery

52 Fox Run Road

Bellingham, MA 02019

508-958-5565

www.highperformancemachinery.com

MD, E. PA, NJ, S. NY, DE

Single Source Technologies, Inc.

2192 Winterberry Ct.

Warrington, PA 18976

610-430-3670

www.singlesourcetech.com

MIDWEST

KS, MO, S. IL

Dynamic Machine Tool, Ltd.

84 Hubble Dr., Ste. 200

St. Charles, MO 63304

636-447-2900

www.dynamicmachinetool.com

N. IL

Integrated Machinery Systems

101 N. Prospect Ave.

Itasca, IL 60143

630-250-8305

www.imscnc.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

www.methods-equipment.com

MN, IA, ND, SD, E. NE, W. WI

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

www.halesmachinetool.com

OH, KY, IN

Technical Equipment

10165 International Blvd.

Cincinnati, OH 45246

800-852-0582

www.techequip.com

MI (upper peninsula), E. WI

Premier Machine Tool Midwest

P.O. Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com

WEST

AZ

CNC PROS

1502 N 17th Ave.

Phoenix, AZ 85007

602-332-5815

www.cnc-pros.com

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

www.ellismachinery.com

CO, WY

AME, Inc. (Adv. Mfg. Eng., Inc.)

5770 Clarkson Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

N. CA, NV (Reno and Carson City)

CNC Solutions

1011 Pecten Court, Ste. A

Milpitas, CA 95035

408-586-8236

www.cncsolutions.biz

S. CA, NV (Clark County)

Protek CNC

25 W. Easy Street, Ste. 306

Simi Valley, CA 93065

805-579-9995

www.protekcnc.com