(l-r) Sam Peltier, Programmer/Toolmaker, and Paul Peltier, Owner, Preferred Tool

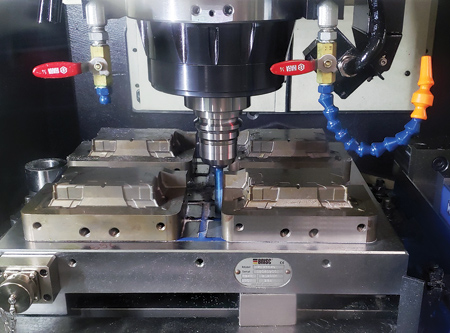

The Yasda CNC Jig Borer YBM-950V at Preferred Tool.

According to Peltier, cycle times are nearly twice as fast due to the higher RPM capabilities of the Yasda CNC Jig Borer YBM-950V.

Preferred Tool designs and manufactures custom-built molds-ranging in size from small, highly accurate to huge, multi-cavity-to customer's exact specifications. Since its inception, the company's goal has been to draw on the expertise of its team to quickly and efficiently provide top quality molds for its diverse customer base.

Meeting production goals in a one-off industry can be a challenge, however. In addition, for Preferred Tool, high accuracy is always a top requirement.

Preferred Tool looked into ways to meet these challenges, including adding new equipment. The company considered a high accuracy CNC machining center, horizontal mill, 5-axis and 3-axis solutions, fixturing (workholding) and CMMs.

Preferred Tool selected a high precision Yasda CNC Jig Borer YBM-950V, a 3-axis CNC vertical machining center (VMC) with a laser and probe. This way operators had the ability to check their work in the CNC mill and make precision changes, resulting in higher tolerance molds. "Also, high precision mills allow for more effective run time with better quality parts and less re-machining," said Paul Peltier, Owner, Preferred Tool, LLC. "The VMC was a step forward-we were able to utilize our current programming capabilities and were quickly up and running."

According to Peltier, the Yasda is working very well. "Having the ability to probe what we cut and then make suitable adjustments has improved machining time and workpiece quality," he said. "Productivity and finish quality have been a bigger benefit than we had planned for."

The compact YASDA CNC Jig Borer YBM-950V is designed for high-speed/high-accuracy machining of small parts, including mold and die parts requiring high-precision contour machining. Features include:

- XYZ travels: 35.4" x 19.7" x 13.8"

- Rapid traverse: 787 IPM

- Feedrate: 196 IPM

- Table working surface: 39.4" x 19.7"

- Spindle: 24,000 RPM, 29 HP

- Laser and touch pad for tool length set-up

- Renishaw probe.

Preferred Tool manufactures medical molds, precision machining and fixtures. "We are running almost exclusively hardened steel components for high production molds with some soft steel machining when needed," said Peltier. "Parts come in with one to two sides ground for holding onto a magnet or for placement in a vise. Typically, side walls are all finished in the machine, along with part detail and shutoffs at the same time. This allows parts to be virtually perfect in location, squareness and flatness."

According to Peltier, the average set-up time went from roughly 10 minutes down to about 5 minutes, plus it has become more accurate. The new solution also allows for the same surface to be machined from different set-ups while still achieving a perfect blend. "Cycle times are nearly twice as fast due to the higher RPM capabilities. Because of the accuracy of the machine, parts only have to be cut once to hit the desired numbers," said Peltier.

Preferred Tool was founded in 1998. "I had been working in the industry and building molds for about 10 years when I decided to try it on my own and see if there was a better way to build a mold. Now, 21 years later, I feel we have accomplished that," Peltier said.

In addition to the Yasda, Preferred Tool capabilities include wire EDM, sinker EMD, CMM, grinders, prototype molds, bridge tooling, hardened production tooling, metal injection molds and plastic injection molds. Software used includes Cimatron, MasterCam and Solidworks.

Peltier recently purchased a tool shop called Imperial Tool, increasing employee count from 9 to 24.

"Our goals have always been to build quality molds in the most efficient way possible and meet our delivery time commitments," said Peltier. "We believe in honest and up-front communication and stand behind our work."

For more information contact:

Paul Peltier, Owner

Preferred Tool, LLC

15195 Freeland Ave N

Hugo, MN 55038

651-429-2418

paul.peltier@preferredtool.net

www.preferredtool.net

Dale Mickelson

Product Manager-Yasda

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

978-443-5388

sales@methodsmachine.com

www.methodsmachine.com