GrabCAD Advanced FDM eliminates the CAD-to-STL conversion process-creating new possibilities for designers and engineers with 3D printing.

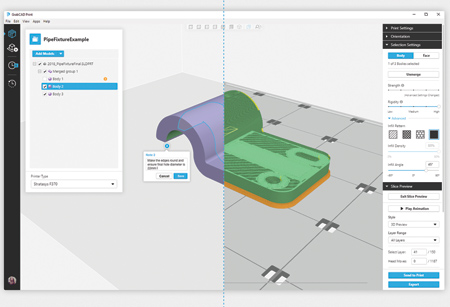

Leaf spring U-bolt fixture, customized using GrabCAD Advanced FDM from Stratasys.

"Stratasys is further removing complexity from design-to-3D print processes. GrabCAD Print's Advanced FDM feature is aimed at ensuring design intent via intuitive model interaction designed to rapidly deliver strong, light and purpose-built parts," said a company spokesperson.

GrabCAD Advanced FDM eliminates the CAD-to-STL conversion process-creating new possibilities for designers and engineers with 3D printing.

"By avoiding laborious CAD-to-STL conversion, users are able to work in high fidelity and rapidly advance the design-to-3D print process, which can lead to boosting both time-to-market and time-to-revenue," said the spokesperson. Advanced FDM is designed to speed part production while maintaining creation of purpose-built parts that minimize weight without compromising strength.

"For design and manufacturing engineers, one of the most frustrating processes is `dumbing down' a CAD file to STL format, only to require subsequent re-injection of design intent into the STL printing process," said Mark Walker, Lead Software Product Manager at Stratasys. "This software is engineered to do away with this complexity, letting designers reduce iterations and design cycles and getting them to a high-quality, realistic prototype and final part faster than ever before."

With rich CAD-native build controls, the solution does not require manual generation of complex toolpaths-cutting overall programming times for 3D printing. Intuitive features achieve desired part characteristics through automatic control of FDM build attributes. Engineers easily select areas on native design geometry and specify design attributes, and Advanced FDM automatically calculates 3D print toolpaths.

Assigning attributes directly to CAD models, users pinpoint areas of strength and rigidity, control infills, ensure sufficient material around holes with inserts and avoid seams. Since toolpaths are automatically generated from model assignments, the user can expect to spend significantly less time on part set-up without losing strong, high-quality, purpose-built FDM parts.

"Advanced FDM has proved invaluable in improving our part processing time. When processing a very large number of tools and fixtures in a very time pressured environment, it was crucial to ensure stronger tool areas were correct first time, every time," said Dave Hewitson, Rapid Prototyping Programmer at McLaren. "Advanced FDM negates the requirement for multiple programs, creating a more streamlined process. It has also allowed us to more effectively control the structure of end-use car parts, something that was previously very difficult with the solutions we had. This means we can get better parts to the track faster."

GrabCAD's Advanced FDM is available via download with GrabCAD Print (from versions 1.24) and is supported on the following Stratasys 3D printing systems: F370, Fortus 380mc, Fortus 380mc Carbon Fiber Edition, Fortus 450mc, Fortus 400mc, Fortus 900mc and F900.

For more information contact:

Stratasys Ltd.

7665 Commerce Way

Eden Prairie, MN 55344

877-489-9449 / 952-937-3000

info@stratasys.com

www.stratasys.com/software

grabcad.com/print/features