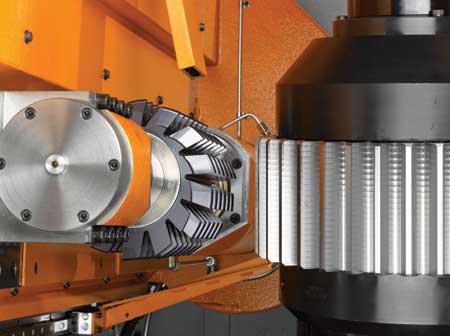

Liebherr LC500 configured with automation.

Liebherr LC 500 work area.

The LC 500 universal hobbing machine is intended to provide high machine availability and productivity, as well as flexibility. It will be demonstrated at Gear Expo 2013, booth 510. Liebherr designed the range of LC hobbing machines for universal applications in general mechanical engineering, the commercial vehicle gear industry and construction machinery, as well as their suppliers.

Market requirements for more flexibility was a key factor in the development of the LC 500, which handles workpiece diameters to 500 mm and a module of maximum 12 mm.

The machine features a one-piece bed. It is available in both automatic and manual operation modes, depending on the specific range of requirements. There are a number of specific configuration options beyond this, from coating and automation as well as drives and cutting heads to additional software modules, according to the company.

"The machines are equipped with fully encapsulated workspaces and spur gears, as well as a highly dynamic, maintenance-free direct drive in the table to deliver premium gear quality," said the spokesperson. "The drive can be a self-cooling spur gear or water-cooled direct drive, based on precision and productivity requirements. Large table bores facilitate the installation of clamping cylinders for workpiece clamping devices.

"Different gear ratios for the water-cooled, zero-backlash tool drive mechanism help to achieve the torques required for high performance processing - with rotational speeds up to 3,000 RPM and drive power of up to 27 kW. The tool mount can be made using a hollow shank taper, ISO short taper or collets. An angular gear is available for worm cutting, which is only mounted as an attachment."

"This machine is not off-the-shelf," said Dr.-Ing. Oliver Winkel, Director of Application Technology and responsible for the technological development of gear cutting for Liebherr Verzahntechnik. "In addition to flexibility, availability and rigidity during processing characterize the machine concept, even in the event of extremely high cutting parameters. Its flexibility and the broad spectrum of components and batch sizes make it especially appealing to contract manufacturers."

For more information contact:

Liebherr Gear Technology

1465 Woodland Drive

Saline, MI 48176

734-944-6369

info.lgt@liebherr.com

www.liebherr.com