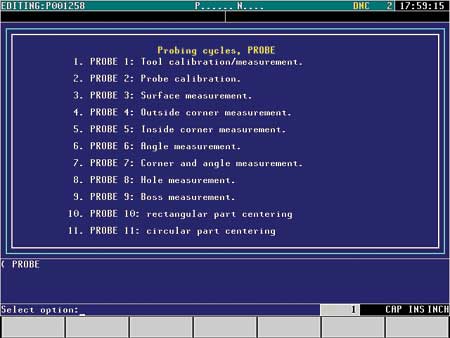

Fagor 8055 CNCs are available with a complete library of easy to program probing canned cycles.

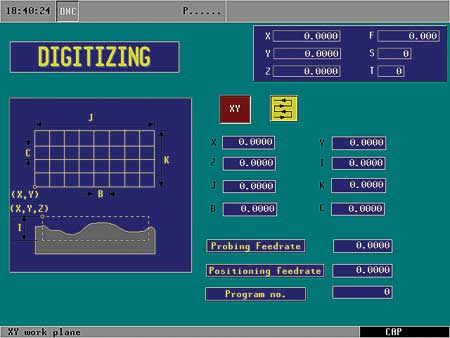

Designed to reduce digitizing set-up time, the simplified CNC digitizing canned cycle allows the operator to quickly set up the machine for digitizing simple or complex parts by utilizing a single fill in the blank page that contains all pertinent parameters for digitizing as well as a graphic assist screen, according to Fagor.

Definitions of the digitizing cycle single page screen include:

- Red key - definition of main plane

- Yellow key - defines the digitizing sweep direction

- X, Y and Z data register - defines the digitizing cycle starting position

- I register - defines the maximum depth probed for contact

- J register - defines the X axes total sweep length

- K register - defines the Y axes total sweep length

- B register - defines the step-over distance between probes

- Probing feedrate register - defines the actual probing feedrate

- Positioning feedrate register - defines the positioning feedrate on the probe retract and step-over

- Program no. register - defines the part program where all probed positional data will be stored.

Upon completion of the digitizing cycle, the programmed point-to-point program created can be edited with feeds, speeds and tool commands and executed or downloaded and further manipulated. The digitizing cycle is available on the Fagor 8055 line of CNC products. Most probing systems are adaptable to the Fagor 8055.

"The 8055 Power CNC was designed to provide the high performance required for performance machine tools, yet maintain a simple programming system when utilized in shop-floor programming applications," said a company spokesperson. "This was accomplished by adding the ICON key conversational system to the ISO G-code programming system. By allowing the ability to combine both programming systems, customer flexibility on the manufacturing floor itself has been increased dramatically. With Ethernet capability, the customer can easily upload/download large G-code programs from the CAD/CAM department, yet also walk up to the CNC and create complex parts directly from the keyboard in a matter of just a few minutes. The Fagor on-board mini-CAD/CAM (profile editor) system allows the customer to create complex profiles directly from the blueprint in only a matter of a few minutes. The profile editor will not just create the profile, but will also automatically create the appropriate G-code and insert it into the program, or you can save the profile as a frequently utilized subroutine with just the push of a single button."

The Fagor 8055 has a built-in graphics mode that allows the customer to plot in solid 3D graphics, solid sectional graphics in multi-plane views simultaneously or in tool path line graphics. This feature can be utilized in simulation mode or in real-time execution mode. In addition a teach-in mode is included, as well as an interactive G-code editor that through a series of graphic interfaces makes G-code creation at the keyboard fast and easy, according to the company.

For custom production environments, the 8055 now allows for OEM or application specific customization. This is accomplished due to the high level parametric programming features coupled with an on-board graphic editor that allows for creation of custom editors and screens. This feature is designed to reduce set-up and even cycle time with dedicated machines in high production environments or specialized application machinery.

"The new 8055 models have advanced machining performance by utilizing a new high performance micro-processor coupled with improved machining algorithms, which effectively doubled the processing speeds thus allowing for dramatically faster cycle times and improved part finish," said the spokesperson.

Utilizing both on-board local PLC I/O and CAN I/O modules, input and output requirements can be built to match the application. The remote CAN modules allow for remote machine placement of the modules that best serve the machine tool. The CNC in intended to provide the flexibility of Sercos or CAN digital servo control and the ability of analog servo control for older machine servo motor systems.

Fagor 8055 CNCs are available with a complete library of probing canned cycles, as well as a full library of turning or milling canned cycles plus equipped standard with value added features such as spindle synchronization, scaling factor, pattern repeat, mirror imaging gantry axes, high level language programming and more. The CNC 8055 Power was designed to function with Fagor digital servo motor systems and absolute linear or rotary encoder feedback products.

Southwest

For more information contact:

Todd Drane

Fagor Automation

800-423-2467 ext. 303

www.fagor-automation.com

Southeast

Joel Kasnik

Fagor Southeast operations

800-423-2467 ext. 302

www.fagor-automation.com

Northeast

Wayne Nelson

Fagor East Coast operations

800-423-2467 ext. 301

www.fagor-automation.com

Midwest

Art Gugulski (CNC)

800-423-2467 ext. 431

Alex Escamilla (DRO)

800-423-2467 ext. 436

Fagor US Headquarters

www.fagor-automation.com

West

Jeffrey Lei

Fagor Automation

800-423-2467 ext. 106

www.fagor-automation.com