Timken TAA Series housed units are designed to make routine bearing maintenance simpler.

The Timken Company, a provider of engineered bearings and power transmission products, has expanded its line of mounted bearings with spherical roller bearing solid-block housed units that allow for easier installation and removal for a multitude of applications.

"Timken spherical roller bearing solid-block housed units with double-nut adapters are designed for tough conditions without being hard to use," said Cory Shaw, Timken General Manager - Housed Unit Bearings. "Not only are our mounted units stronger on the outside, but they are also smarter on the inside. We design our units to provide high performance, real world maintenance solutions in a wide range of sizes and styles."

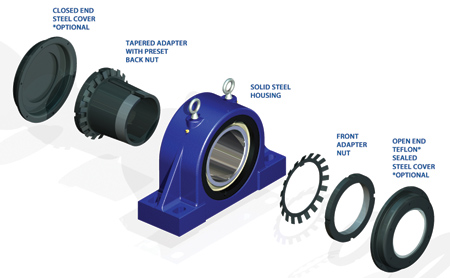

Timken spherical roller bearing solid-block housed units now come in sizes up to 15" (380 mm), including the new TAA Series units, with added conveniences for customers. Inside each TAA Series unit is a double-nut, tapered adapter sleeve designed to simplify bearing replacements in challenging environments.

Timken modified its standard adapter sleeve (with front lock nut) to include a mechanical withdrawal nut on the back end that is factory set for nominal shaft sizes and, if necessary, can be easily adjusted in the field to accommodate actual (under/over) shaft size.

The front locking nut is tightened until the back nut stops against the face of the inner ring, indicating that proper bearing clearance and mounting force has been achieved. This eliminates the need for difficult and often inaccurate in-process measurements of radial internal clearance, helping MRO professionals reduce time on the job and improve consistency. (Note: the adapter sleeve can also accept hydraulic nuts.)

For quick dismounting, the front nut is loosened so the back nut can be tightened to unseat the sleeve from the tapered bearing bore, assisting in bearing removal.

All TAA Series housed units use a Timken double-row spherical roller bearing to deliver enhanced performance in many types of applications including mining, steel processing, bulk handling, power generation, forest products cement and more. Mounted bearing advantages include:

- Loading capacity does not change regardless of housing orientation

- Ability to handle up to 1.5° of misalignment

- Rigid one-piece, cast-steel housing withstands shock loads and the impact of falling debris

- Contact and non-contact primary seal options for enhanced protection

- Optional secondary sealing covers available for all standard units

- Easy in-field conversion from fixed to floating with one rotation of the retaining nut.

For more information contact:

The Timken Company

4500 Mount Pleasant St NW

North Canton, OH 44720

234-262-3000

www.timken.com