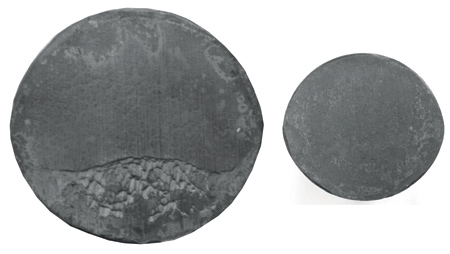

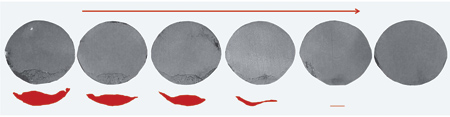

(left) Part with shearing break-out, produced with a mechanical bar stop. (right) Part without shearing break-out, produced with the servo hydraulic bar stop.

The servo hydraulic bar stop minimizes the break-out through progressive force increase during the production.

The servo hydraulic bar stop ensures that the distance between blade and bar stop is constant throughout the whole shearing process.

Hatebur has presented its servo hydraulic bar stop. The technology is designed to make metalforming manufacturers more productive. "The servo hydraulic bar stop optimizes the shear surface and boosts the quality of forged parts. That facilitates and speeds up the quality control and can make post processing obsolete. The technology enhances the productivity of manufacturers," explained Hatebur CEO Thomas Christoffel. The Swiss enterprise, a global provider in forming machines and tools, will offer the new technology on a variety of machine types.

The innovation targets the first step of the metalforming process. Before the parts are formed in the various forming stations, the inductively heated steel bars need to be sheared off with high precision. In the past, the shearing process led to a slight tilting and an oblique position of the sheared part. "Besides that, the shearing process changed into a tearing process towards the end, resulting in what is referred to as shearing break-out," said Christoffel. Sometimes scuffing was generated at the sheared surface, which needed to be removed from the finished forged parts by sandblasting. If these scuffing were pressed onto each other during the forming process, the producers needed to post process the parts by metalcutting.

Minimized Scuffing

Due to the servo hydraulic bar stop, the tilting and oblique positioning can be reduced, and the surfaces are now virtually parallel. "Now, scuffing is rarely generated, and thus is practically never pressed into folds," explained Dr.-Ing. Mihai Vulcan, an employee of Strategic Projects at Hatebur.

Since 2017, Hatebur has been testing the technology thoroughly in a development partnership with a European automotive supplier. It was tested on a Hatebur HOTmatic HM75 XL. The results: The scuffing on the shearing surface was able to be minimized from 20% of the surface to just 1%. The new bar stop technology also minimized or eliminated the shearing break-out. This resulted in quality improvement of the parts, facilitating and speeding up the visual control after the sandblasting. Christoffel said, "If the quality control can be accelerated by only half a second per part, the technology already brings a real benefit to our customers."

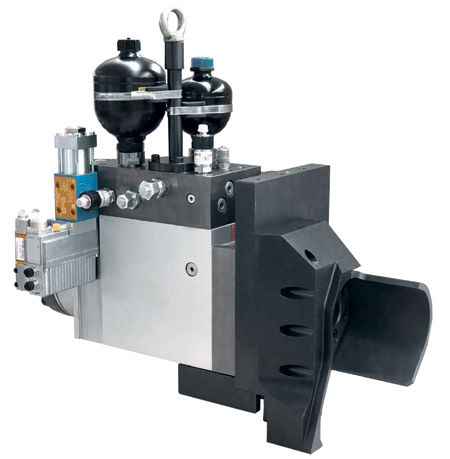

Position and Force Control

The shearing process, depending on the bar diameter and the machine speed, takes between 60 milliseconds and 100 milliseconds. "Only a servo hydraulic drive can offer the necessary dynamics and power density in a small space," said a company spokesperson. The inter-divisional project team of Hatebur, led by Mihai Vulcan, applied an alternating position and force control. Should at the end of the in-feed movement the bar stop deviate from its target position even by only a few hundredths of a millimeter, the position of the bar stop will be immediately adjusted via the servo valve. "This position control allows us to keep the actual distance between the blade and the bar stop constant during the whole shearing process," emphasized Mihai Vulcan.

After the shearing process starts, the control shifts to a force control with position monitoring. Throughout the process, the integrated measuring technology records the process data.

When deviations are recognized, the automatic control adjusts imbalances immediately, providing an optimized surface quality.

"Hatebur, founded in Switzerland in 1930, employs an international network of fully owned subsidiaries and sales partners to provide products and services that are never far away from its customers. After an in-depth consultation and design process, Hatebur offers a machining solution for producing high volumes of precision metal parts that meets the customer's needs and requirements," said the spokesperson.

For more information contact:

Hatebur

1486 Medina Road, Suite 209

Medina, OH 44256

330-239-2222

www.hatebur.com