Waterjet Nozzles

April 1, 2019

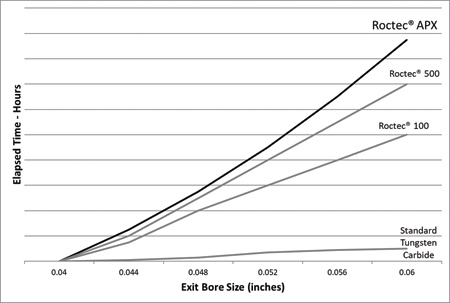

"The ROCTEC APX nozzle provides up to 20% longer life compared to its nearest competitor, the ROCTEC 500," said a company spokesperson. It is suitable for aerospace, medical, electronics and other industries.

"Kennametal offers its next-generation ROCTEC APX waterjet nozzles that provide 20% greater life than ROCTEC 500 waterjet series," said a company spokesperson. The APX nozzles are suitable for use in precision cutting applications where long, uninterrupted cuts or close tolerances must be maintained for long periods to maintain part integrity or minimize expensive scrap due to premature nozzle failure.

"We are always trying to push the boundaries of performance, and we heard from customers the need for even greater productivity-to make longer cuts, gain more flexibility and produce better parts on their waterjet machines," said Jeff Gardner, Key Account Manager at Kennametal. "At the same time, waterjet machine builders continue to develop higher pressure pumps and more efficient cutting processes. ROCTEC APX is a next-generation nozzle designed to meet these needs."

"Using APX series nozzles, waterjet shops can take on even more challenging, complex jobs or run at faster production speeds or longer production periods. It also enables customers to better integrate technology advancements, including advances in waterjet pumps and cutting head technology," said the spokesperson.

For more information contact:

Kennametal Inc.

1600 Technology Way

P.O. Box 231

Latrobe, PA 15650

724-539-5000

www.kennametal.com

< back