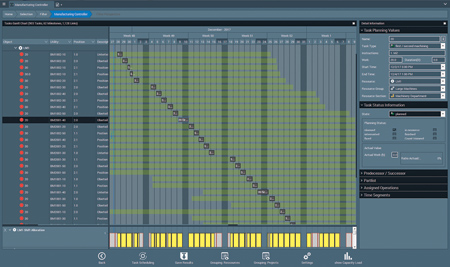

ProLeiS control center shows a display of assignment plan with time frames.

Tebis America, a software company specialized in CAD/CAM systems for design and manufacturing servicing tool, die, mold, automotive and aerospace manufacturing industries, has announced that ProLeiS MES System is now available as a product of Tebis. Going forward, ProLeiS will act as a new business unit of Tebis under the name Tebis ProLeiS GmbH.

"The complexity of single-part manufacturing in die and mold manufacturing requires end-to-end solutions for production that connect all participants - the project managers and planners, purchasing agents, designers, schedulers, programmers, manufacturing and assembly staff, stock managers and external suppliers. Tebis now offers comprehensive data management, manufacturing planning and manufacturing control functions with ProLeiS (MES) that enable effective control of all individual parts for dies and injection molds-from quotation to the finished product," said a company spokesperson.

Project managers can quickly and easily check during pre-planning to determine whether proposed projects can be processed and required delivery dates met. They also have a clear understanding of all processes. This is provided by overviews of milestones, degree of completion of dies and resource assignment.

Once planners, project schedulers and those responsible for manufacturing create more detailed project plans, ProLeiS offers fast and convenient tools to organize and control capacity. All manufacturing steps for the individual parts are defined and scheduled using standardized planning templates. Once planning is complete, a supply of orders is provided for each resource-employee or machine-for processing in the specified sequence.

Purchasing agents will find the system beneficial with the ability to order the material and outsource in ProLeiS and integrate the suppliers in data management via the vendor interface. All parts are ready on time at the machine and in the assembly area before manufacturing starts.

Employees in design, manufacturing and programming can use ProLeiS to manage all data and approvals. Approved orders automatically appear in the order supply for the subsequent instance. The system's flexibility enables changes such as rush orders or modifications to be included at any time.

"Tebis has developed a concept for implementing ProLeiS that provides a quick start of the system," said a company spokesperson. "Experts from Tebis Consulting analyze the company's processes and model its resources and processes in the ProLeiS and Tebis client/server environment." Manufacturing planning and control as well as data management are generated in company-specific steps. All project participants can now work quickly and effectively with the apps assigned to them for their respective user roles. The apps can be used on mobile devices to access data and evaluations-or via the internet.

For more information contact:

Tebis America

400 E. Big Beaver Road

Troy, MI 48083

248-524-0430

info@tebisusa.com

www.tebis.com