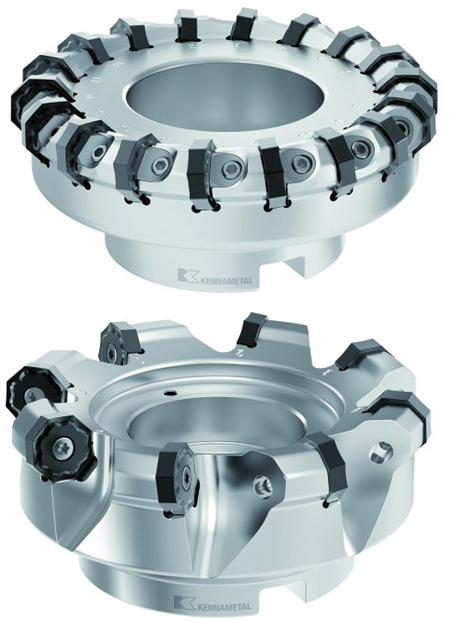

Mill 16 split case design. The largest split case cutter body weighs only 20.4 kg (48.45 lbs.).

Wedge style and screw-on style cutters in fine, medium and coarse pitch cover all cast iron roughing and semi finishing applications.

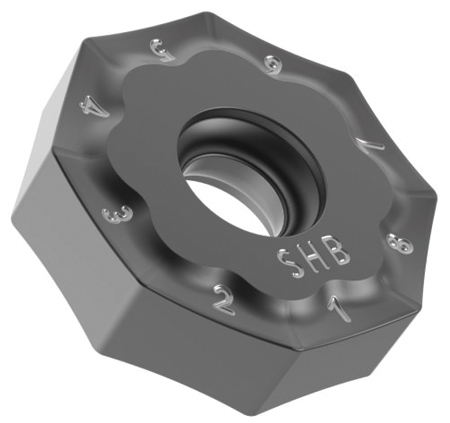

The double sided, 16-edged insert provides low cost per edge.

KCFM consistently achieves surface finishes of Rz13 (Ra 0.8 µm) with peak to peak wave heights (Wt) of 10 µm or less.

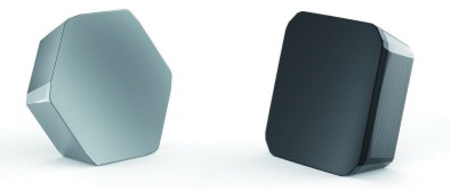

Hexagon shaped inserts with wiper facets provide high productivity. When applying square shaped inserts for the adjustable pocket seats, even better surface finishes of Rz 2 can be achieved. The grades portfolio provides flexibility. Carbide grades, ceramic grades and full top PCBN offer high cutting speeds.

Kennametal has expanded the Mill 16 platform by introducing new cutter body styles, insert geometries and grades, and a split case design for large diameter bodies that reduces spindle bearing loads.

With these new additions, the portfolio is designed to fit any cast iron face milling application: from fine pitch wedge style cutters for high productivity and powerful machines to medium and coarse pitches screw-on cutters when horsepower is limited; and from machining of small components to very large components.

The Mill 16's split case design is engineered to meet massive machining needs, with wedge-style cutter bodies ranging from 300 to 500 mm (12 to 20") in diameter. "For those worried about hanging huge cutters off their machine spindles, there is good news: the largest split case Mill 16 cutter body weighs only 20.4 kg (48.45 lbs.), and is still able to rotate at up to 2,800 RPM (almost 15,000 SFM)," said a company spokesperson.

All cutters use the same multi edged (16 cutting edges) design insert that provides low cost per cutting edge.

Finishing of Cast Iron

"To an engine manufacturer, flatness and finish is everything," said the spokesperson. "Without it, leaks are sure to occur, leading to expensive warranty claims and unhappy customers. The same can be said for those making transmissions, hydraulic manifolds, pump bodies and anywhere a smooth sealing surface is needed. Unfortunately, the material used to make many of these components-cast iron-can be challenging to machine.

"There are many options available on the market for fine finishing of cast iron, and most of them can achieve the required surface finish. However, deterioration of the finishing occurs as soon as the inserts show slight wear. That causes an increase in cutter pressure, resulting in vibration, and feeding marks are observed. The result is downtime due to frequent insert exchange."

Kennametal Cast Iron Finishing Milling (KCFM), with the new KBK50 full top polycrystalline cubic boron nitride (PCBN) grade, was developed to address these issues.

"Now customers can produce more parts per edge in a reliable and consistent manner, so the cost per component will decrease," said the spokesperson. "Machining time reduces drastically since PCBN can be applied with three times higher cutting speeds compared to carbide inserts."

There are more options with KCFM available than just PCBN. Combining the semi-finishing KY3500 silicon nitrate ceramic with KBK50 finishing wiper inserts is also a productive and cost-effective solution for customers who do not want to have a full load PCBN inserts in the cutter. PCBN and ceramic grades are suitable for mass production and stable conditions.

In many cases there is also the need for fine finishing on unstable conditions, such as weak workpiece clamping, limited spindle speed, long overhang or when tooling cost is the primary consideration. Designed for light to medium machining, the carbide grade KC514M is engineered to meet these challenges. A TiAlN PVD coating is both tough and wear resistant. KC514M can be applied with or without cutting fluids.

For more information contact:

Kennametal Inc.

1600 Technology Way

P.O. Box 231

Latrobe, PA 15650

724-539-5000

www.kennametal.com