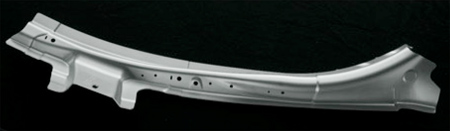

HFQ technology deep-drawn, high-strength aluminum A pillar installed in 2016 Aston Martin DB11. Tight internal bend radii enhance occupant sight lines.

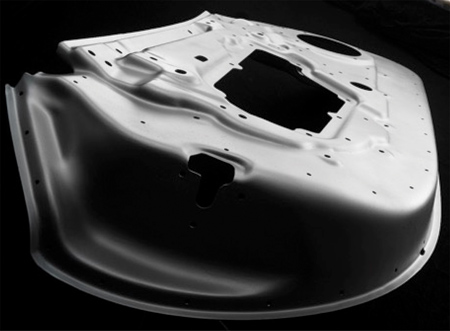

HFQ Technology high-strength inner door panel produced in a single deep-drawn operation. With a yield strength of 300 MPa, the pressing demonstrates complexity of form coupled with strength enabled by HFQ technology.

HFQ Technology complex cross member with varying thicknesses, achieved through a stir welded tailored blank with 32% less mass than cold formed counterpart.

Hot Form Quench (HFQ) technology from Impression Technologies Ltd. (ITL) combines stamping and heat treating in a single operation to produce complex aluminum components up to 20% lighter than cold formed grades.

"Unlike conventional cold formed aluminum stampings that require separate reinforcement assemblies that add thickness and bulk, HFQ fabricates thinner, fully formed parts through an integrated process that is simpler, faster and less costly," said Tim McGuire, North American Business Development Manager for ITL.

"European OEMs are replacing steel and cold formed body pillar supports, door reinforcement panels and other structural and multi-piece assemblies with HFQ Technology components that help lower carbon emissions and improve fuel mileage," McGuire added. "ITL is developing a global network of Tier 1 suppliers to provide OEMs with HFQ pressings."

HFQ technology heat treats 6000 or 7000 series range aluminum blanks and transfers them to a stamping press where they are formed at high speed and quenched in the tool. "This proprietary in-die process produces highly complex geometries from ultra-high-strength grades of aluminum, and this is what sets HFQ apart. Coupled with the reductions in weight, HFQ technology also reduces development and operational costs as part counts are simplified as are tooling processes. This opens up a whole new opportunity for both low and high-volume automobile manufacturers to capitalize on the benefits of HFQ technology," McGuire said.

HFQ simulation software enables design engineers to craft one-piece pressings with shapes that are lighter and stronger, with reduced springback for environments in which they will function. Customers can lease the software or license HFQ Technology for mass production of complex parts with repeatable precision. ITL also provides design services and produces prototypes and limited product runs for customers.

For more information contact:

Impression Technologies Ltd

info@impression-technologies.com

www.impression-technologies.com