Cut MX Grooving and Parting Tool

May 1, 2018

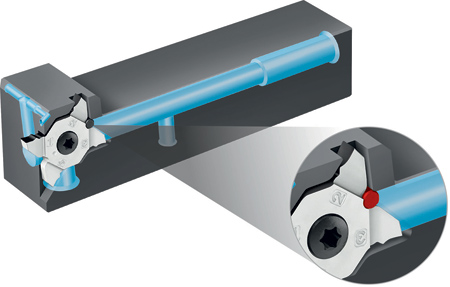

Walter Cut MX grooving and parting off tool

The new Walter Cut MX grooving and parting tool is designed to improve accuracy, stability and process reliability. These indexable inserts feature four cutting edges per insert. Inserts are offered in three different geometry types (GD8, CF5 and RF5), and Tiger·tec Silver PVD coating. The self-aligning, tangential clamping of the MX system and the dowel pin location in its insert seat result in greater repeatability.

"It is impossible to fit the inserts incorrectly in the Walter system, which makes handling reliable," said a company spokesperson. In addition to the high-precision toolholder system with precision cooling, the inserts' Tiger tec Silver PVD is engineered to maximize tool life.

Walter Cut MX geometries offer enhanced chip control, particularly the CF5 sintered geometry. The inserts have four precision ground cutting edges. Cutting depths of up to 6 mm and cutting widths from 0.8 to 3.25 mm are available in the standard range.

Due to the precise center height and the cutting edges, the system is suitable for precision grooves, circlip grooves and small diameters. The Walter Cut MX is suitable for small parts manufacturers with requirements for high accuracy. The efficiency of the system is such that only one type of cutting insert is required for both the left- and the right-hand toolholders. If one cutting edge breaks, users can continue working with the rest.

For more information contact:

Walter USA, LLC

N22 W23855 Ridgeview Pkwy. West

Waukesha, WI 53188

800-945-5554

www.walter-tools.com/us

< back