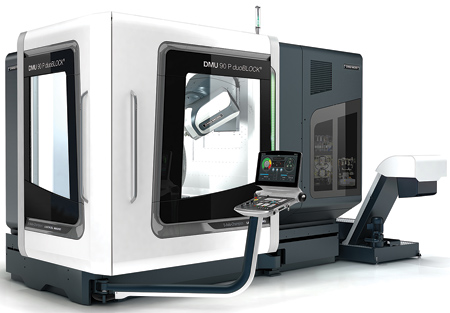

The DMU 90 P duoBLOCK allows an economical entry into heavy-duty machining.

DMG MORI has introduced the DMU 90 P duoBLOCK, featuring a high-performance motor spindle and 60 SK50 tools in its standard version.

According to the company, 5-axis machining is also the trademark of the fourth generation of the successful duoBLOCK series. Features include the stable design of the universal machines, long-term accuracy and high precision with up to 4 µm positioning accuracy even in the standard version. It is designed as a package machine with a high-performance motor spindle, space for 60 SK50 tools and IKZ coolant unit and provides an economical entry into heavy-duty machining.

According to the company, applications in tool and moldmaking as well as in general mechanical engineering call for investment in reliable, high performance production equipment. The DMU 90 P duoBLOCK is geared especially towards the universal machining typical for tool and mold making and mechanical engineering. With an X-axis travel of 35.4" and workpiece weight of 3,970 lbs., it outperforms the smaller DMU 80 P duoBLOCK.

The equipment package of the DMU 90 P duoBLOCK includes a vertical chain magazine with space for 60 SK50 tools and a 69.7 HP motor spindle. With 12,000 RPM and a torque of 317 ft-lbs., it is designed to handle even demanding machining tasks. A spindle growth sensor, machine protection control and a 600-liter IKZ coolant unit with 40 bar and 23 l/min round off the basic machine.

Numerous options mean the basic machine can be adapted individually to meet higher requirements. A motor spindle achieves 15,000 RPM and a torque of 297 ft-lbs. The tool magazine can be expanded to 90 SK50 pockets, with HSK A100, BT50 and CAT50 toolholders also available as an alternative plus a 980-l, 80-bar IKZ coolant unit. Workpiece measurement in the work area using a Blum laser system and a 3-D quickset can also be implemented.

The standard version of the DMU 90 P duoBLOCK is equipped with CELOS and a SIEMENS 840D solutionline. The HEIDENHAIN TNC 640 3D control is also available as an alternative.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com