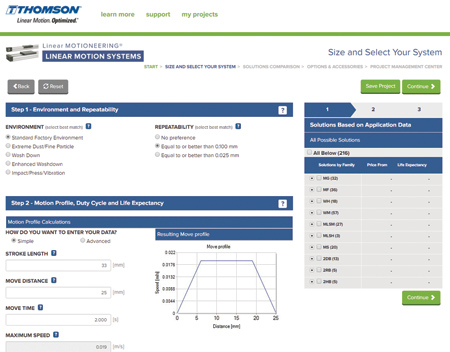

The improved Linear MOTIONEERING sizing and selection tool is designed to provide an effortless navigation experience to users who seek real-time adjustments and quick filtration settings.

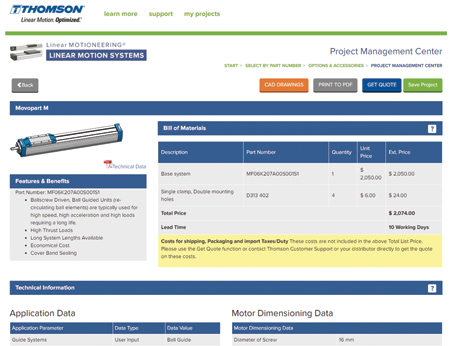

Thomson's online tool helps design engineers choose the most suitable solution for their applications. Once they have decided on the systems, a detailed BOM is available, disclosing information such as the price, lead time, features and benefits of the products.

Movopart linear unit

WH (SpeedLine) linear unit

WM (PowerLine) linear unit

Thomson Industries, Inc. has enhanced its Linear MOTIONEERING product sizing and selection tool for linear motion systems, reducing the time for component selection from hours to typically less than 15 minutes. The tool retains the engineering calculations that are effective for design engineers and has added new product families, interactive navigation, expanded global support and mobile access.

"Linear motion system designers are under increasing pressure to get competitive products to market quickly," said Kyle Thompson, Thomson Product Line Manager-Systems Group. "We are fully committed to helping them do so by making system sizing as fast and effortless as possible. Our upgraded online selection capabilities enable them to specify linear motion units like ball screw driven ball guided units or belt driven slide guided units with the same ease of use and efficiency as one might expect from an e-commerce site or mobile application, while still having the confidence that their decisions are backed by the full weight of the Thomson engineering knowledge base."

Thomson used the latest online best practices to upgrade the Thomson Linear MOTIONEERING: Linear Motion Systems product selection tool. With the new navigation, users make all selections on a single screen. As they enter parameters, the system recalculates in real time, instantly revealing how each choice impacts their available options. This gives them the opportunity to make unlimited changes without ever needing to navigate to another screen. Once satisfied, the user simply accepts the choice and receives the complete orderable bill of materials (BOM) and ordering materials.

System designers who already know what products they need will benefit from faster, more intuitive product filtering and comparisons. It is now easier for them to filter products on the attributes that most impact engineering calculations, such as cover type, material choice or environmental resistance. Or, they can simply enter part numbers and receive the BOM immediately. Comparison tables sort options based on variables such as price, highest safety factor and lifespan.

Where the original tool was used primarily in North America, the new tool has been enhanced for global use. In addition to English, it is available in German and Chinese and the associated currencies (U.S dollar, Euro, Swedish Krona and Chinese Renminbi). The tool has been tested and optimized for the most popular tablets and smart phones.

Thomson's web tool includes products from the following families:

- M (Movopart) linear units: These are ideal for economical, transport-grade applications such as packaging, material handling and factory automation. The units are versatile since there are two drive options (belt or ball screw) and two bearing guide options (slide or ball guide).

- WH (SpeedLine) linear units: Belt-driven and wheel-guided, these units are designed for dynamic applications requiring throughput and smooth motion, including high-speed material handling and packaging.

- WM (PowerLine) linear units: These ball screw-driven, ball-guided units combine high precision with stiffness and rigidity for applications such as machine tool automation and test/measurement.

"Like the motion control industry, we know that interactive technology does not sit still, and we are committed to delivering our customers the most advanced online ordering technology available as quickly as we can," said Thompson. "We are already at work on augmenting our product selection capability to enable more intuitive motor sizing mounting and will soon enable complete online e-commerce capability across our product lines."

The online tool is available at www.linearmotioneering.com.

For more information contact:

Thomson Industries, Inc.

203A West Rock Road

Radford, VA 24141

540-633-3549

Thomson@thomsonlinear.com

www.thomsonlinear.com