"The new 3D point measuring cycle helps to accelerate quality assurance processes," said a company spokesperson.

3D residual stock: Optimized complete machining for roughing

OPEN MIND presents hyperMILL 2014.1.

OPEN MIND Technologies AG, a developer of CAD/CAM software and postprocessors, has released version 2014.1 of the hyperMILL CAM solution. According to the company, the CAM suite is designed with more powerful basic features, improved automation options and new tools.

"Reamers, barrel cutters in different designs and lens cutters can be fully exploited with the new version of hyperMILL," said a company spokesperson. "The new 3D point measuring cycle helps to accelerate quality assurance processes."

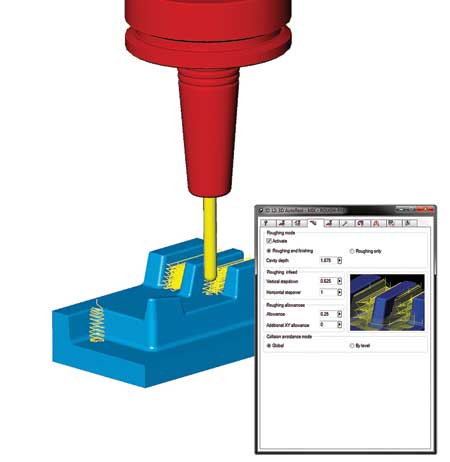

Automatic Rework Machining

According to the company, improved 3D rest machining allows for the automatic detection of rest material areas where additional roughing is necessary. Additional roughing passes are calculated for these areas. 5-axis rework machining has also been improved. When converting from 3-axis toolpaths to 5-axis toolpaths, different tool types such as barrel and woodruff cutters can be used. There are also new strategies for adjusting the tool to the machining model. The new function can also be used for the hyperMAXX high-performance cutting module and inherit variable technology values.

CAD Deformation

hyperCAD-S, the CAD system for CAM programmers, has been supplemented with the Deformation module for the customized deforming of geometries. "This modification tool allows the global or local modification of component areas, which is otherwise only possible with elaborate modeling techniques," said the spokesperson.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Avenue, Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com