Delcam to Demonstrate at Anaheim Exhibition

January 14, 2015Delcam will demonstrate the latest developments in its range of CAM programming software on Feb. 10-12 at the Pacific Design & Manufacturing exhibition. The event will take place at the Anaheim Convention Center in Anaheim, CA. "The main highlights will be the 2015 R2 releases of the FeatureCAM feature-based CAM software and of the PowerMILL software for the programming of high-speed and 5-axis machining," said a company spokesperson.

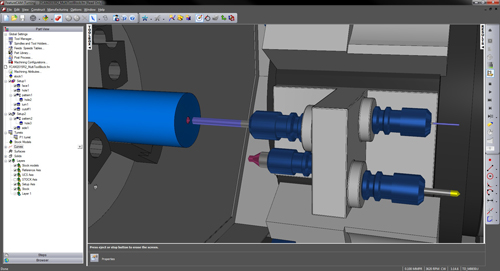

FeatureCAM 2015 R2 is designed to create multi-tool blocks within machine designs.

FeatureCAM 2015 R2 incorporates a milling calculator designed to help users obtain the maximum benefit from the Vortex high-efficiency area-clearance strategy. "The radical nature of Vortex can make it difficult for users to set the optimum parameters when they first apply the strategy," said the spokesperson. "To address this issue, Delcam has added a calculator that uses control of the maximum chip thickness to calculate the appropriate feeds and speeds that will minimize the cutting time while maintaining a consistent load on the cutter."

Other enhancements, among the 280 customer-requested improvements since the initial 2015 release last September, include the ability to create multi-tool blocks within machine designs, better control over toolpath output and more efficient automatic selection of tools.

According to the company, a similar number of improvements can be found in the 2015 R2 version of PowerMILL. The new release includes improvements in toolpath simulation and verification, area clearance and drilling, plus more options for customization by users.

"The enhanced simulation in the new version allows complete verification of a project for machine-tool issues such as collisions, rather than having to undertake verification of each individual toolpath in turn," said the spokesperson. In related improvement, automatic collision checking of area-clearance toolpaths now takes into account any remaining stock on a model, both when checking the cutter and the toolholder. In addition, all toolholder collision checking for area clearance takes place during toolpath calculation, allowing the user to ensure that these toolpaths can be free of toolholder collisions. Simulation has also been improved with the addition of the ability to simulate machine-tool movements as tool changes are executed.

"Another important development is a new rib-machining module for PowerMILL that has been introduced to speed up and simplify the machining into tooling of cavities to form ribs," said the spokesperson. "Reinforcing ribs are required in many types of plastic moldings, from electrical housings to containers to furniture. They are typically much deeper than they are wide, which poses special challenges when machining the cavities needed to form them. In many cases, these challenges prompt companies to use EDM to form the features rather than machining.

"The new PowerMILL module makes it easier and safer to program the machining of cavities for narrow ribs, even when the cutter's length is greater than its diameter. Using the dedicated rib-machining strategy gives a better surface finish than using a standard finish machining option and also improves efficiency by limiting the number of air moves."

For more information contact:

Delcam

877-335-2261

marketing@delcam.com

www.delcam.com

www.delcam.tv/fc2015

www.delcam.tv/pm2015/lz

www.pacdesignshow.com

< back