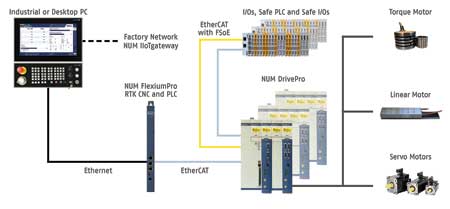

NUM FlexiumPro system architecture

For more than 60 years, the Swiss company NUM AG, a provider of CNC solutions, has been offering a basic system for CNC systems in a wide range of applications. As part of the continuous development of the CNC platform, the new FlexiumPro is replacing its predecessor, Flexium+.

The focus of further development is on performance, speed, precision and reliability. With this in mind, the hardware configuration for the new version of the CNC platform, consisting of a real time kernel (RTK) with CNC and PLC, the drive amplifiers (NUM DrivePro), the servomotors and the required PC, has been comprehensively revised.

"FlexiumPro achieves a significant increase in reliability and system availability, not least thanks to the integration of PLC and CNC processes on a single board based on a multicore ARM processor," said a company spokesperson. "By using system-on-chip technology, NUM has succeeded in increasing the CNC computing power of FlexiumPro tenfold compared to the last version of Flexium+, with strict synchronization of CNC and PLC."

Flexium+ relies on a real-time operating system. "This avoids latency times and the complexities usually associated with soft operating systems and ensures precise control and responsiveness," said the spokesperson. "All data, such as the PLC program, machine configuration, workpiece programs and calibration data, are stored on a removable micro SD card, which represents an additional advance, not least in terms of data security. The system is also protected by the integration of supercapacitors in the FlexiumPro Real Time Kernel. This ensures that the system shuts down safely even in the event of spontaneous power failures."

FlexiumPro seamlessly follows on from the previous versions in terms of functionality and also expands on them. New features include:

- Control of up to 32 axes and/or spindles

- Support for 32 processing channels

- Free auxiliary channels and PLC axes

- Sub-nanometer interpolation

- Real Tool Center Point (RTCP)

- High-speed cutting (HSC)

- Specific technology functions and processing cycles

- Improved diagnosis

- Modern and intuitive human-machine interface (HMI) that can be easily customized.

In addition to the familiar functions, the retention of the PLC programming language and environment as well as the upward compatibility of the workpiece programs facilitate a smooth migration from Flexium+ to FlexiumPro. In addition to interoperability, FlexiumPro's new HMI focuses above all on flexibility. With the help of the Software Development Kit (SDK), FlexiumPro can be extensively customized. For example, customer-specific modules or plug-in components can be integrated.

The launch of the new FlexiumPro CNC platform will be supported by the introduction of another new series of high-performance drives in the NUM DrivePro series in 1-, 2- and 4-axis configurations for controlling all types of electric motors.

For more information contact:

Steve Schilling

NUM Corporation

603 East Diehl Road, Suite 115

Naperville, IL 60563

630-505-7722

sales.us@num.com

www.num.com