Entering IPCs into ProShop at each machine saves steps, prevents errors and helps with RXI's AS9100 compliance.

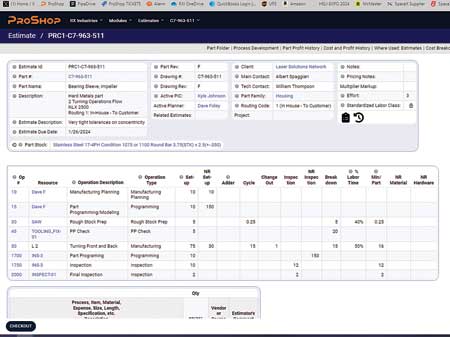

RX Industries relies on the ProShop's Estimates module for quick creation of cost and time estimates for parts and assemblies. Estimates can be created from scratch or through the Rapid Estimate Template system.

Due to the intuitive nature of ProShop, work order layouts are readily available and include process steps, pictures, videos and write-ups of all that is expected for each job.

At RXI, temperature control and the latest equipment and software allow for tight-tolerance manufacturing. Pictured is the RX Industries team.

U.S. Air Force four-star General Lloyd "Fig" Newton (Ret.) visits RX Industries. The manufacturer serves the aerospace, military and space sectors.

"Customers are family at RX Industries, Hilton Head, SC. Picnics on the island are made better with customers who become friends," said a spokesperson.

From the age of 13, Tom Rougeux tagged along on his father's business trips and gained exposure to the world of manufacturing. Rougeux's dad, a professional engineer and lifelong manufacturing executive, took his son to facilities like Whirlpool and other production plants throughout the Midwest, where he explained the inner workings of manufacturing processes. Those factory visits made an impression.

Years later, after earning a degree in finance and economics, Rougeux was happily employed in the engineering sector. Even so, the idea of owning his own business took root. He kept an eye out for the right opportunity, and in September 2020, Rougeux and his wife Sarah purchased a South Carolina machine shop. RX Industries was officially in business.

"Our company was launched in the middle of the pandemic," said Rougeux, President, RX Industries, Hilton Head Island, SC. "For us, it was actually a good time to start a company because we did not have the usual pressures of everything having to move at American speed. My wife convinced me to purchase the assets of a machine shop that had just been started by a young couple that passed away. Out of that tragedy, RX Industries was born."

RX Industries employs 12 people in its 10,000 sq. ft. production facility. Hilton Head Island, known for its pristine beaches and world-class golf courses, has higher-than-average manufacturing costs. To offset those costs, RXI focuses on high-end markets, mainly the aerospace, military and space sectors. Contracts include spectrometer equipment for NASA satellites, satellite parts for space companies, laser equipment for U.S. fighter jets, components for the U.S Department of Defense weapons systems and commercial medical equipment. Attracting customers with stringent manufacturing requirements was definitely by design, according to Rougeux.

"We could not stay in business by taking on simple jobs. That would never get our bills paid. So, we built the company around high-end markets," Rougeux said.

Before he started his own company, Rougeux had a clear vision of what it should look like and sought the tools he needed to realize that vision. He knew that implementing an enterprise resource planning (ERP) system at the outset was imperative. In a previous job, Rougeux served as the ERP implementation manager, so he was quite familiar with the software benefits.

"I knew that an ERP system was going to be required because the industries that I wanted to serve were going to require their vendors to have process management under control," he said. "We always wanted to pursue space, military, medical and high-end industrial markets. Those industries are not kind to companies without good processes and good process control.

After extensive research, Rougeux compiled a list of more than 270 possible software solutions and eventually narrowed them down to six serious contenders, one of which was ProShop ERP. A phone call to Paul Van Metre, President and co-founder of ProShop, led to a three-hour review session and ended Rougeux's ERP quest. RXI implemented its ProShop system at the end of 2020.

"We peeled back that onion every way from Sunday. When Paul and I hung up, I knew that ProShop was the only contender at that point," Rougeux said. The deciding factor was ProShop's Flying Start package in which the quality management systems (QMS) was not an add-on module. Embedded into all of ProShop's modules, it can be used to manage and certify a company to any quality standard, including ISO 9001, AS9100, ISO 13485, American Petroleum Institute (API) and more.

"No one had that. And to my knowledge, no one has it to this day," Rougeux said. "ProShop's ability to provide me with a logical, honest ramp to near-term and long-term success was a slam dunk."

Rougeux continued, "I dream of hiring people, paying them very well and being a virtuous company that does things entirely differently than what is considered normal in the industry. To get that done, I knew we had to have systems and processes in place on day one. ProShop has met that need in spades."

A major benefit of the ERP system is its paperless format. All job details are immediately available to RXI programmers and machinists. Last minute changes are no longer a concern because outdated information is immediately archived. Specifications are viewed in real time. Customer changes occur, of course, but since implementing ERP, RXI has never accidentally made an incorrect revision based on obsolete data.

The intuitive nature of ProShop was a huge selling point for Rougeux. Work order layouts are readily available and include process steps, pictures, videos and write-ups of all that is expected for each job. "There is very little opportunity for introduction of error when doing things like end-process checks," Rougeux said. "In most shops, employees are writing numbers on pieces of paper, those numbers are transcribed to a spreadsheet and that spreadsheet is then used to craft the inspection report. We just put the numbers in the inspection report directly from ProShop and we are good to go. It is an extremely elegant process."

Because the software was created by machine shop owners for machine shop owners, the platform is user friendly. Its web-based navigation system is easy to learn, according to Rougeux, who added that most of his employees have epiphanies when they realize that the software brings efficiency to all areas of the company. Training time is minimal as most RXI employees learn the system basics within two days. They continue to hone their ProShop skills and gain an ongoing appreciation for the system benefits.

One ERP system benefit that keeps RXI running smoothly is the Tooling module, which manages and tracks all consumable tooling and permits recording and searching of tool features. The module displays tool crib inventory and reveals which tools are currently in use in a work cell. Tool cost and purchasing history are available along with vendors, lead times and work order details. Active tooling requirements and triggers for minimum inventory values are managed in the Purchasing module using the shopping cart system.

The Tooling module helps RXI in two critical areas. First, Rougeux and his team are always aware of inventory. They know when to order materials due to a safety quantity in the ERP Tooling module that alerts them when they get low on something. Second, RXI purchases its tools through several different vendors. Within the module, parts are referenced by EDP numbers. As vendors have different names for the same part, the EDP reference allows the RXI team to shop by EDP. The Tooling module provides a list of vendors that can provide tooling, pricing, delivery dates and vendor ratings, which helps RXI with its ISO requirements.

The ERP saves RX Industries money and time, particularly when it comes to scheduling. Over one weekend, for example, Rougeux received a request to run five different parts, eight parts per batch. All required turning operations and were difficult to cut. Due to ProShop's Scheduling module, Rougeux was able view the RXI production schedule from his smartphone and inform his customer that he was able to run the parts within 15 days, but he needed extra time for the milled part. Responding to the customer inquiry on a Saturday allowed the customer to make a decision by Monday morning.

"The Scheduling module allows us better utilization of our machines. If we know what jobs we are looking for, we do not have to waste time quoting jobs that we cannot do right now," said Rougeux.

Rougeux added that his favorite benefits of the ERP system are the quoting process and the templates for workflow processes. After receiving a request for quotation, he can have a professionally consistent quote in his customer's hands within a half hour, sometimes sooner. The Estimates module allows quick creation of cost and time estimates for parts and assemblies. The estimates can be created from scratch or through the Rapid Estimate Template system. Process flow creation tracks labor and cycle times, raw materials, bill of materials items, out-of-plant processes and more. With a simple mouse click, a finalized estimate can be generated into a quote.

"The Quoting module provides a consistent quote for the scope of work involved," said Rougeux. "Because everything is data driven, the software takes out subjectivity."

RX Industries realized accelerated growth and has become a vibrant, high-end CNC machine shop due to key decisions, such as implementing an ERP system and choosing ProShop. As they acquire their AS9100D certification and serve the aerospace markets, the employees at RXI already know how to flow work to achieve a seamless and accurate end result. Rougeux believes that as his company prepares to double in size over the next 15 months, the ProShop partnership is essential to its success.

For more information contact:

ProShop USA, Inc.

11 Bellwether Way, Suite 201

Bellingham, WA 98225

800-990-4046

contact@proshoperp.com

www.proshoperp.com

RX Industries

16 Finch St.

Hilton Head Island, SC 29926

843-802-4137

contact@rxind.com

www.rxind.com